It has been ten years since I started this blog. When I first posted on September 1, 2013, I never though that it would go on this long. But it has. Now there are 525 blog posts (or 663 if you include the Chinese and German translations) and a total of 765 000 words with (mostly?) high-quality content on lean manufacturing and related topics. Time to look back and also to celebrate!

It has been ten years since I started this blog. When I first posted on September 1, 2013, I never though that it would go on this long. But it has. Now there are 525 blog posts (or 663 if you include the Chinese and German translations) and a total of 765 000 words with (mostly?) high-quality content on lean manufacturing and related topics. Time to look back and also to celebrate!

NoRepost

These posts have timely content (anniversaries, birthdays, etc.) that would look odd if re-posted. Hence, this catzegory reminds me not to repost these articles for twitter etc.

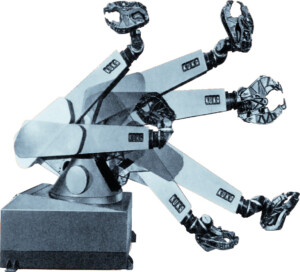

KUKA FAMULUS Turns 50—The First Modern Industrial Robot

SMED 2.0—A Changeover for the Changeover

Single Minute Exchange of Die (SMED) to reduce and shorten changeover times is one of the best-known methods in lean manufacturing. However, the original steps as shown by Shingo have, in my view, potential for improvement. Hence, I restructured the changeover workshop based on my experience with SMED to make it easier and more straightforward. This rework is not groundbreaking or revolutionary, but merely a few small changes to make it easier to use. As it is popular nowadays, I also added a 2.0 after SMED for my SMED 2.0.

Single Minute Exchange of Die (SMED) to reduce and shorten changeover times is one of the best-known methods in lean manufacturing. However, the original steps as shown by Shingo have, in my view, potential for improvement. Hence, I restructured the changeover workshop based on my experience with SMED to make it easier and more straightforward. This rework is not groundbreaking or revolutionary, but merely a few small changes to make it easier to use. As it is popular nowadays, I also added a 2.0 after SMED for my SMED 2.0.

Making the Problem go Away Is NOT Improvement

Managing problems  is an important part of manufacturing because it allows companies to identify and address issues that can impact product quality, production efficiency, and overall profitability. However, it is not to be confused with actual improvement. While taking care of the problem (hopefully) makes the problem go away, actual kaizen requires that the problem should not come back.

is an important part of manufacturing because it allows companies to identify and address issues that can impact product quality, production efficiency, and overall profitability. However, it is not to be confused with actual improvement. While taking care of the problem (hopefully) makes the problem go away, actual kaizen requires that the problem should not come back.

Akio Toyoda Steps Down as Toyota CEO

Somewhat surprising to industry insiders, the CEO of Toyota Motor, Akio Toyoda, announced on January 26 his resignation, and he will step down as CEO on April 1, 2023, to become the chairman of the board. Hence, I will have a look at his impact on Toyota. However, just to be warned, if you expect glowing praise, you should look elsewhere. I believe he changed Toyota, a company I love, in a worrisome way. I am definitely not a fan of his work. Granted, being a CEO is not easy, and he did have to lead Toyota through a couple of crises (Recall,s Corona, etc.). Compared to other CEO’s, he is probably somewhere around average. But I believe he had a negative influence on the Toyota corporate culture.

Somewhat surprising to industry insiders, the CEO of Toyota Motor, Akio Toyoda, announced on January 26 his resignation, and he will step down as CEO on April 1, 2023, to become the chairman of the board. Hence, I will have a look at his impact on Toyota. However, just to be warned, if you expect glowing praise, you should look elsewhere. I believe he changed Toyota, a company I love, in a worrisome way. I am definitely not a fan of his work. Granted, being a CEO is not easy, and he did have to lead Toyota through a couple of crises (Recall,s Corona, etc.). Compared to other CEO’s, he is probably somewhere around average. But I believe he had a negative influence on the Toyota corporate culture.

The Impact of ChatGPT on the Future of Work

You may have heard of ChatGPT, the latest buzz in artificial intelligence. ChatGPT is a chatbot by OpenAI that can answer your questions and hold a conversation. And, it is very good at this. It can handle almost anything connected with text. This tool (and the many others that are likely to follow) has the ability to fundamentally change how we work. Let me show you.

You may have heard of ChatGPT, the latest buzz in artificial intelligence. ChatGPT is a chatbot by OpenAI that can answer your questions and hold a conversation. And, it is very good at this. It can handle almost anything connected with text. This tool (and the many others that are likely to follow) has the ability to fundamentally change how we work. Let me show you.

250 Years of the Cromford Cotton Mill – Start of the Industrial Revolution

The Industrial Revolution is arguably the most significant change in manufacturing history. Since it was a gradual process over almost a century, the exact start and end dates are hard to pin down. However, for me one of the key dates is the start of the first cotton mill in Britain, the Cromford Cotton Mill by Richard Arkwright. Construction of this mill started in 1771, and production began 1772, which is 250 years ago, hence time for me to write an anniversary post on the Cromford Cotton Mill.

The Industrial Revolution is arguably the most significant change in manufacturing history. Since it was a gradual process over almost a century, the exact start and end dates are hard to pin down. However, for me one of the key dates is the start of the first cotton mill in Britain, the Cromford Cotton Mill by Richard Arkwright. Construction of this mill started in 1771, and production began 1772, which is 250 years ago, hence time for me to write an anniversary post on the Cromford Cotton Mill.

Happy 9th Birthday, AllAboutLean.com

Yet another year has passed. AllAboutLean.com is now nine years old! I never though I would keep it up for so long, but your support and encouragement for my writing keeps me motivated. Many thanks! I am looking forward to writing many more years on the topic of lean. I also have more books planned (but this will take some time). Anyway, let’s review the year:

Yet another year has passed. AllAboutLean.com is now nine years old! I never though I would keep it up for so long, but your support and encouragement for my writing keeps me motivated. Many thanks! I am looking forward to writing many more years on the topic of lean. I also have more books planned (but this will take some time). Anyway, let’s review the year: