Amazon uses a pretty neat and nifty way to store its materials using robots. These are commonly known as Kivas, although Kiva is only the name of the company that originally invented them. Amazon calls them Amazon Robotics. In this post I will look in detail at both the design of their storage pods and how Kivas manage their inventory.

Amazon uses a pretty neat and nifty way to store its materials using robots. These are commonly known as Kivas, although Kiva is only the name of the company that originally invented them. Amazon calls them Amazon Robotics. In this post I will look in detail at both the design of their storage pods and how Kivas manage their inventory.

Introduction

In a recent series of posts, I described in detail how the Amazon Fulfillment Centers work. Below is the overview of the flow of material and information in an Amazon Fulfillment Center.

But their robots especially are a great topic. I talked a lot about Kivas in my previous series of posts, especially how they work, how the stowing process works, and how the picking process works. Basically, these robots lift an entire shelf, bring the entire shelf (called a “pod”) to picking or stowing, where an item is removed or added, and then take it back to the storage area. Below is a short video edited from the Amazon newsroom that shows the robots moving around, and another video that shows the picking process.

Storage Strategies with Kivas

Looking at this made me wonder, What is a good storage strategy for these pods? One of Amazon’s goals is to fit the most material into their warehouse. If this would be the only goal, then they should just pack as many pods as possible. This is illustrated as a top-down view on the left. This has the largest capacity and utilizes 100% of the space. However, the disadvantage is obvious: You can’t really get your material out without shifting everything else around. If you would do this in reality, you probably could use around 80% to 90% of the space, while the rest you need for shifting things around. Higher percentages means more time for shifting and vice versa.

Looking at this made me wonder, What is a good storage strategy for these pods? One of Amazon’s goals is to fit the most material into their warehouse. If this would be the only goal, then they should just pack as many pods as possible. This is illustrated as a top-down view on the left. This has the largest capacity and utilizes 100% of the space. However, the disadvantage is obvious: You can’t really get your material out without shifting everything else around. If you would do this in reality, you probably could use around 80% to 90% of the space, while the rest you need for shifting things around. Higher percentages means more time for shifting and vice versa.

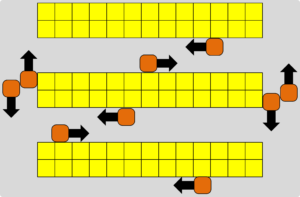

So let’s look at another option. This is inspired by a warehouse with very good access to the material using two-lane traffic. Depending on how many intersecting lanes you have, this will utilize somewhere between 25% to 50% of the space. The example shown here with thirteen pods between intersecting lanes has an utilization of 43% of the space.

So let’s look at another option. This is inspired by a warehouse with very good access to the material using two-lane traffic. Depending on how many intersecting lanes you have, this will utilize somewhere between 25% to 50% of the space. The example shown here with thirteen pods between intersecting lanes has an utilization of 43% of the space.

However, most warehouses do not have two-way traffic between the shelves. Instead there is only one lane between shelves. In this case the space usage would be somewhere between 44% and 66% depending on the number of intersecting lanes. The example shown here with an intersecting lane every 7 pods has a space utilization of 58%.

However, most warehouses do not have two-way traffic between the shelves. Instead there is only one lane between shelves. In this case the space usage would be somewhere between 44% and 66% depending on the number of intersecting lanes. The example shown here with an intersecting lane every 7 pods has a space utilization of 58%.

If you have only a few forklifts, this would not need to be regulated. But with literally hundreds of Kivas running around on a single warehouse floor, you probably would need to design lanes for one direction only.

So, how does Amazon arrange their storage? The answer did surprise me a bit, but look at the screenshot from an Amazon video below.

Amazon arranges their pods in clusters with one-way lanes in between. The majority of these clusters were 3×6, 3×7, 4×6, and 4×7 clusters, with an occasional supporting pillar in between. This gives you a space use between 64% and 70%, significantly more of any of the other feasible options above. It does create a bit of a shuffle to get a pod out from inside the cluster, but it seems to work. Also note that they keep the traffic lanes straight all the way through from end to end. This is probably to allow better acceleration, but also to reduce the likelihood of items falling out during a turn.

Amazon arranges their pods in clusters with one-way lanes in between. The majority of these clusters were 3×6, 3×7, 4×6, and 4×7 clusters, with an occasional supporting pillar in between. This gives you a space use between 64% and 70%, significantly more of any of the other feasible options above. It does create a bit of a shuffle to get a pod out from inside the cluster, but it seems to work. Also note that they keep the traffic lanes straight all the way through from end to end. This is probably to allow better acceleration, but also to reduce the likelihood of items falling out during a turn.

There are also clusters of 3×4 and 4×4 closer to the picking areas, and you can also find a few 2×7, 2×6, and 2×3 clusters. These look like storage pods containing more frequently requested parts, although Amazon claims completely random storage. Besides, you could also store more frequently used parts at the edges of the clusters anyway. You will also find a traffic area for the robots to move around between the storage area and the picking and stowing operators. In comparison, Alibaba and their similar Quicktron robots use clusters of mostly 2×5 and 2×6, avoiding any shuffling since every pod is directly accessible.

In sum, using these robots gives Amazon a storage space utilization of probably around 65% (assuming a bit of shuffle space but excluding the traffic area toward picking). This is much better than their manual storage options as shown below. For manual storage they probably have a space usage of of less than 60%. This 5% does not sound like much, but for Amazon with around 175 fulfillment centers, this is the equivalent of 8 fulfillment centers (although only a few of them use robotics, and most still have manual picking and stowing).

Pods Design

Amazon Kiva systems store inventory in pods. These pods are a simple metal structure with shelves on all four sides. They have a square base of 1m by 1m (39×39 inch). This square base makes it easier to fit them in in any direction. They are somewhere between 180 and 240 tall (6-8 feet).

There are different types of pods (including some for heavy-duty items), but all of them have a metal superstructure. Some pods have cardboard shelves, but the most common type I have seen are actually hanging textile shelves. Yes, the shelves are hanging from the top. If you look at the picture of the picker, you can clearly see loops at the top.

There are usually storage options on all four sides. Two opposite sides have many small shelves across the entire surface that are not very deep. The two other sides have deeper shelves, but only in the middle. The left and right parts of these sides are blocked by the shelves on the other sides. These deeper shelves are all the same size.

There are usually storage options on all four sides. Two opposite sides have many small shelves across the entire surface that are not very deep. The two other sides have deeper shelves, but only in the middle. The left and right parts of these sides are blocked by the shelves on the other sides. These deeper shelves are all the same size.

The smaller shelves, however, differ in size. There are five levels that are quite low. Above and below are a total of three more levels that are a bit higher. There is one more level at the bottom that is significantly higher than any other level. If you ever had anything to do with ergonomics, you will notice that the smallest levels are at the most ergonomic access. This is no coincidence, and Amazon placed these levels so that most interactions are at a comfortable height for the operator. Please note that there are also different styles with a different number of compartments.

Naturally, all slots have a human readable label for rows A, B, C… and columns 1, 2, 3. Additionally, there is a 2D code for the scanner. To prevent items from falling out, an elastic strap is strapped across every level of the pod. This is simply clipped onto textile loops that are part of the hanging shelf. You can see these too in the photo above.

In my next post I will show you the different types of robots that Amazon uses, and how their latest generation of robots will give them much more flexibility. Until then, stay tuned, and go out and organize your industry!

I work for Amazon. and I believe pod design needs to be reevaluated. It is not the best design. Items fall out of the bins ( ALT). Some items get damage, customers orders get delayed. cost of picking the inventory from the floor and processing back in to the bins. All the cost gets add up.