For all your products, you have to decide between make-to-order and make-to-stock. A similar decision is needed for components or raw materials that you produce or purchase. As described in my precious posts, the key criteria is the quantity and the fluctuation. In this last post in this small series I will look at where to make the cut, and what other factory play a secondary role for your production system.

Where to Put the Split

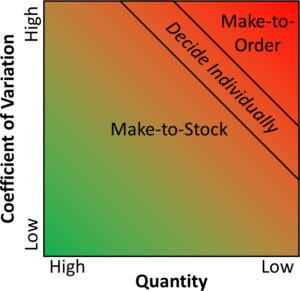

As described in the last post, make-to-order and make-to-stock depends on the quantity and the fluctuations of the item sold. For all your items you could make an ABC-XYZ analysis (although you don’t have to bother about how much for A, B, etc., but only make a plot), or a similar plot of the fluctuations over the quantity.

As described in the last post, make-to-order and make-to-stock depends on the quantity and the fluctuations of the item sold. For all your items you could make an ABC-XYZ analysis (although you don’t have to bother about how much for A, B, etc., but only make a plot), or a similar plot of the fluctuations over the quantity.

For the question on where to split between make-to-order and make-to-stock, I would approach this from both sides. I would look at the extremes with the lowest quantity and the highest fluctuations, and would consider them make-to-order products. Especially if you have products that are heavily customized and produced or even developed only if a customer orders the item.

On the other end, you have the high-quantity products with the least fluctuations. These are often prime candidates for make-to-stock. From those extremes I would move toward the middle and decide for each item between make-to-stock and make-to-order. If you are still in the corners, then the decision is probably easy. However, the smaller the gap between the two groups, the more you may want to think about the decision. Below I have a few additional criteria that can help you to decided. Depending on your business, you may end up with 100% make-to-stock or 100% make-to-order, but most businesses have a mix in between.

Make-to-stock has higher inventory costs, but some customers cannot or will not wait for a make-to-order production. At the end of the day, you want to use the approach that gives you and your company the best benefit for the effort.

Also, it may be best to look at individual products rather than product groups. A product group may be mostly make-to-order or make-to-stock, but they still may have a few products for the other category. Best to look at each product separately.

Additional Factors

Impact of a Stock-Out

Probably the next most important criteria after the quantity and fluctuations is the problems you will have if you have a stock-out. There are multiple possible scenarios. The easiest one is if you have a monopoly and power over the customer. If you don’t have the item available the customer is forced to wait, but will buy it from you anyway. In this case, there is no additional pressure to produce make-to-stock, as the only risk is a slightly damaged reputation. Another scenario is not a monopoly, in which case the customer buys from the competition. A missed part merely means a missed sale and maybe also a lost customer.

The critical situation is if the customer has power over you, and will cause you a lot of trouble if there is a missing product. To be more precise, this is a situation where the customer cannot accept a waiting time longer than the replenishment time. Assume, for example, you produce for a car maker. Even though the product is needed only in small quantity and with high fluctuations, a delay in delivery may lead to the final assembly line at the major car maker being stopped. This will cost the car maker around $1 million per day, and they quickly make your life uncomfortable with late penalties and forwarding the cost to you. These products may be better produced as make-to-stock, unless the contract permits make-to-order production.

Another example would be infrequently used medicine. Let’s take as an example a snake-bite antivenom. This may not be needed very often, but once you need it, you don’t want to start milking snakes to produce it. Hence, despite its low and highly fluctuating demand, it is an item that should be produced make-to-stock. Luckily, the customers are willing to pay for this item to be produced to stock.

Product Shelf Life

Another smaller factor may be the shelf life of the product. If the product has a long shelf life, it has no impact on the decision between make-to-order and make-to-stock. However, if it is a product which expires quickly (e.g., fresh food), there is a risk that it will expire before it is sold, in which case you have to cover the loss. This makes make-to-stock production more expensive, and may nudge you toward make-to-order production. That does not mean that all short shelf life products are make-to-order, but it is one factor in the decision.

Quality Issues

Another smaller aspect is if the product has frequent quality issues. If not, then this is not a factor. But if it has quality issues, a make-to-order production can give you faster feedback between production and finding the problem. This faster feedback can help in finding the cause of the issue and resolving the problem. Again, it is not a key factor, but if you have a product where it is difficult to decide, this may nudge you toward make-to-order.

Cost and Size of the Product

Another minor aspect is the cost and/or the size of the product. The decision between make-to-order and make-to-stock is basically the question of which option is more profitable. All other things being equal, an expensive product ties up more capital than a cheap product. Similarly, a large product has more storage cost than a small product. Other less common situations may be a product that needs to be stored at -70°C vs. a similar product that can be stored at room temperature. Again, it is not a big factor, but it may influence your decision for the products where you are not yet certain.

Fluctuations in Purchasing or Production

The fluctuations we looked at so far were demand fluctuations. However there may also be supply fluctuations. If your supplier does not have a reliable delivery turnaround, you may also be inclined more toward make- (or purchase-) to-stock, especially for raw materials and purchased components.

Limitations

There may also be limitations, mostly for make-to-stock items. The more you produce make-to-stock, the more storage space you need and the more capital you have sitting idle on your shelves. Storage that you have available is cheaper than storage that you need to get or rent. Hence, once your inventory is full with make-to-stock items, you may be a bit more hesitant to include even more products as make-to-stock. You cannot always avoid it, but the available storage space and capital may also be a (smaller) influence on your decision. Also, keep in mind that you should not fill up your storage space to 100%, as you will then no longer have room for the inevitable fluctuations.

This concludes my short series on the decision between make-to-order and make-to-stock. I hope it was helpful for you. Now, go out, ponder the decision between make-to-order and make-to-stock, and organize your industry!

This was an extremely well done article, as someone who sees a future in the food industry I loved the comparisons that were made. One of the biggest takeaways is first looking at the demand of your good. If you are a sandwich shop and you know you sell 150 Bacon Chicken Ranches a day in comparison to only 30-40 chicken cutlet sandwiches. It may be smart to make BCRs every hour and stock up on them to be prepared when an inevitable order or rush comes. However, doing this for a cutlet sandwich could result in waste. Unlike sandwiches sometimes making a stock, for example machinery is smart as it has no shelf life and can be in a warehouse for years.