If you are in lean, you surely have heard of kaizen, and its English translation, continuous improvement process (CIP). It is one of the fundamental parts of lean. Kaizen generally means to improve, and in lean in particular, it means to continue improving forever. Pretty much all companies that haven’t gone bankrupt do this, often without using the word kaizen. You need to continuously improve in order to survive the harsh realities of competition.

If you are in lean, you surely have heard of kaizen, and its English translation, continuous improvement process (CIP). It is one of the fundamental parts of lean. Kaizen generally means to improve, and in lean in particular, it means to continue improving forever. Pretty much all companies that haven’t gone bankrupt do this, often without using the word kaizen. You need to continuously improve in order to survive the harsh realities of competition.

Linguistics

Kaizen is Japanese for “improvement” or “betterment.” The word itself does not say anything about this being a continuous or repeating process, and in normal Japanese it could be only a single improvement. However, in Japanese business ethics, the repetitive process is pretty much always implied. The word kaizen consists of two Japanese characters: 改善. The first one 改 means “reformation, change, inspection, search.” The second means “virtuous or good.” Overall, it is improvement.

Kaizen is Japanese for “improvement” or “betterment.” The word itself does not say anything about this being a continuous or repeating process, and in normal Japanese it could be only a single improvement. However, in Japanese business ethics, the repetitive process is pretty much always implied. The word kaizen consists of two Japanese characters: 改善. The first one 改 means “reformation, change, inspection, search.” The second means “virtuous or good.” Overall, it is improvement.

The Basic Idea

You are probably familiar with the basic idea of kaizen: Keep on improving. If you do not continuously work on getting better, you will fall behind. Or, as it is commonly said in English, you have to run just to stand still.

Different Types of Improvements

You can distinguish improvement into different types if you want. There is troubleshooting and problem solving, and then there is actual improvements. The boundary between these two is actually fluid, but it helps to keep in mind that there is more to kaizen than just firefighting, even though many shop floors are mostly occupied with solving problems that pop up.

Troubleshooting

Even a very well set-up production system will degrade over time. Machines and tools age, and their performance may suffer if there is no maintenance. Things will break. Sometimes you notice right away because the breakdown causes a lot of problems, and this forces you to fix it immediately. Other times the issue will be more subtle, and you may not even know that you have a technical defect, except that your quality or performance is slipping. The system also changes due to external factors. New products are developed, and what may have worked well for the old products may not work well for the new ones. The customer wants more (or fewer) products than before. You get a new supplier, maybe because the old one is out of business. All of this forces you to change your production system just to keep your company from going under.

Even a very well set-up production system will degrade over time. Machines and tools age, and their performance may suffer if there is no maintenance. Things will break. Sometimes you notice right away because the breakdown causes a lot of problems, and this forces you to fix it immediately. Other times the issue will be more subtle, and you may not even know that you have a technical defect, except that your quality or performance is slipping. The system also changes due to external factors. New products are developed, and what may have worked well for the old products may not work well for the new ones. The customer wants more (or fewer) products than before. You get a new supplier, maybe because the old one is out of business. All of this forces you to change your production system just to keep your company from going under.

However, fixing problems and troubleshooting is only one part of the different improvement efforts. Another part is prevention of problems through preventive maintenance and similar activities. I leave it up to you to decide if you consider this an actual “improvement” (i.e., kaizen) or not, since it only maintains the status quo, but you should not neglect it.

Actual Improvement

Besides fixing and preventing problems, there is actual improvement. The system runs, and there are no major issues like machine breakdowns, but it could run even better. What can you do to improve the system performance? Could you establish a pull system? Should you improve work standards? What about improving the shop floor layout to improve performance?

Besides fixing and preventing problems, there is actual improvement. The system runs, and there are no major issues like machine breakdowns, but it could run even better. What can you do to improve the system performance? Could you establish a pull system? Should you improve work standards? What about improving the shop floor layout to improve performance?

Most companies are almost completely preoccupied with firefighting. Only very lean and well-organized companies spend a lot of their efforts on actual improvement. If you are not sure which type your company is, then it is probably the former. Some truly lean companies like Toyota actually spend a lot of effort merely to find out where they still could improve.

As I said above, these two groups actually overlap quite a bit, and this classification is not a tool to distinguish projects, but more of a philosophical aid to show you that there is more to improvement than what blows up in your face.

Where to Start?

This brings up the question on where to start your kaizen efforts. This is not an easy question. You should know your true north. What are the overarching goals of your company? At least some of your improvement efforts should be geared toward this true north. If you are using Hoshin Kanri, it may help to give you a better understanding of the direction the company should be moving. Especially for larger projects, Hoshin Kanri or a similar overarching direction is very helpful.

There are also the firefighting projects. These often take priority. It is of no use to develop a beautiful pull system if your tools are broken and you do not produce anything.

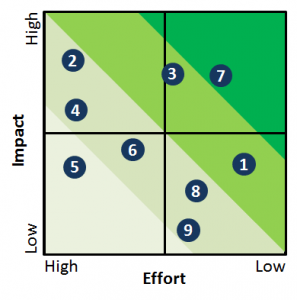

An impact effort matrix can help you prioritize projects. You try to get the biggest bang for the buck. See more on prioritization in my post How to Manage Your Lean Projects – Prioritize. Some of your kaizen projects may be large, take time, and include multiple people. Do not underestimate the many things that can go wrong in large projects. Smaller steps are often easier.

An impact effort matrix can help you prioritize projects. You try to get the biggest bang for the buck. See more on prioritization in my post How to Manage Your Lean Projects – Prioritize. Some of your kaizen projects may be large, take time, and include multiple people. Do not underestimate the many things that can go wrong in large projects. Smaller steps are often easier.

Other kaizen projects may be very small, include only one or two people, and can be implemented quickly using duct tape and some string. Often, if it looks useful and can be done quickly, then you should just do it. Even starting an impact effort matrix may be more effort than doing the quick improvement in the first place. Such quick kaizen efforts are often particularly good to raise morale.

How to Proceed

So now you know where you want to do kaizen. But there are still many things that can go wrong. For me, there are a few key points that are more important than others:

Management Support: Any kind of successful project needs support from management. And by this I do not only mean that management allows it, or even wants it; they need to put their weight behind it. If you want to become lean, it is not enough that you want to lose weight; you actually need to do a lot of exercise to become lean. This may even require additional manpower or time to do the actual improvement. At Toyota, they have an amazingly large number of people to help with the kaizen effort, whereas in many other companies the task is merely slapped on top of already-overworked people.

Management Support: Any kind of successful project needs support from management. And by this I do not only mean that management allows it, or even wants it; they need to put their weight behind it. If you want to become lean, it is not enough that you want to lose weight; you actually need to do a lot of exercise to become lean. This may even require additional manpower or time to do the actual improvement. At Toyota, they have an amazingly large number of people to help with the kaizen effort, whereas in many other companies the task is merely slapped on top of already-overworked people.

Worker Involvement: It really helps if the improvement is done together with the people whose area is affected. Do not change a machine without talking with the workers first. They may not command your salary, but they usually know the shop floor better than anyone else does.

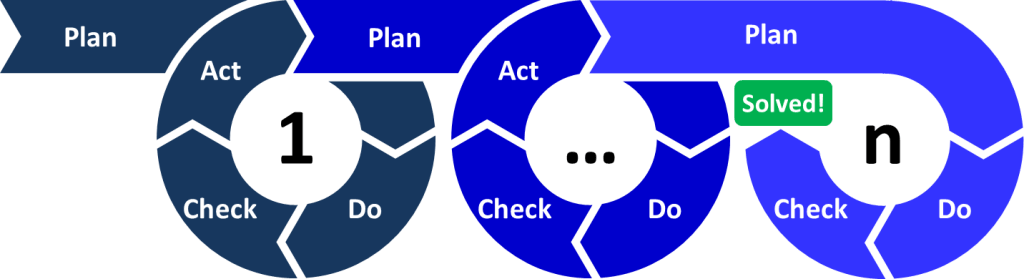

PDCA: Plan–Do–Check–Act are crucial for any kind of project. For me, this is one of the most important philosophies to achieve success. Many people want to achieve a lot in little time and do Plan-Do-Plan-Do-Plan-Do… but end up achieving nothing. The Check and Act are essential to ensure that your improvement is actual an improvement (kaizen 改善), and not a changing for the worse (kaiaku 改悪).

So this is the brief overview on how to do kaizen. While tools like SMED have a clear approach in seven steps (or similar), kaizen is much more fuzzy and harder to nail down. I hope this was useful to you, and gives you a little bit of guidance in the “softer” parts of lean manufacturing. Now go out, improve your system, and organize your industry, and keep on doing this forever!

I was introduced to the notion of Kaizen in Japan in 1985. Like most approaches to improvement (and good management in general) it suffers here as being a ‘flavour’, and having various interpretations / semantics attached to it. One aspect that is often overlooked is that one cannot improve without knowing where you are at the moment: the practical nuts n’bolts aspects of kaizen build upon standards.

I’ve worked with many companies that see the appeal of engaging all their workforce in continuous improvement – and of low-cost / no-cost money-in-the-till change, rather than costly innovation. But when it comes to agreeing>setting>training>monitoring>maintaining standards it all falls down. Standardisation is essential, to avoid creativity being wasted on continuous firefighting to stand still, and allow kaizen to flourish.

Actually, 改善 is originally Chinese characters or called it as “kanji” in Japan. But it is true that Japan is keeping more original meaning for some Chinese characters than China today.

Like many other words in the TPS/Lean lexicon, I struggled long & hard to understand the real meaning of the word Kaizen. My breakthrough came from the realisation that real understanding of the meaning of a word was not to be achieved from the study of the characters & letters of the words themselves; but from studying the behaviour, attitudes & results their application creates. It is useful to see that organisational performance has two dimensions – speed & accelerations. To compete successfully in the race for global business, we must manage these two dimensions. Like any other race, success in the long term business race does not go to those moving the fastest at any given time, but those accelerating faster than everyone else in the race. It doesn’t matter if initially you are the last, as the Japanese were in cars, cameras, electronics etc., as long as you improve/accelerate faster than everyone else you will win. The Japanese have demonstrated the effectiveness of this system and have a name for this acceleration/improvement process; it is Kaizen. It is their word for all the activities that continuously improve everything we do & create. To achieve the maximum acceleration rate we must engage all our people in this process. To truly understand Kaizen, I think it helps to remember the words of Archimedes; “Give me a lever long enough & I can lift the world.” Our people’s combined abilities are the lever to raise our organisation’s performance to world class levels & keep it there. Kaizen is the focus/fulcrum for its application.

For me Kaizen has several meanings. Kaizen workshops can be small improvements involving a few employees, linked to the meaning of “continuous improvement”. Kaizen events applied to processes (manufacturing or transactional) (Value Streams..) can involve up to several tens of process actors depending of process complexity. In this case the meaning is more realted to “breakthrough” improvement. As an example, implementing Kaizen events (with an ad-hoc structure and ad-hoc priority system) delivered some years ago and after 2 years of implementation 5B$ yearly savings with world class quality of products and services and employees satisfaction, within a major US corporation (200 000 employees with complex products and complex organization)

I had a hard time understanding the aspects of Kaizen. I agree with what you have said here that Kaizen is all about implementing, analyzing and practice so that we could make changes as needed and improve processes. I think Kaizen goes with the old saying “practice makes you perfect”. Gaining the benefits of continuous improvement. I believe at the organizational level Kaizen can be a very powerful approach that harnesses suggestions and involvement from people at every level.

Good article. In my experience, this is often limited to a notional concept or a phrase that is used in Corporate paralance. Even with companies that carry out Lean training and do continuous improvement projects, the system is often not adequately set up for this to become intrinsic to the company’s culture, where Kaizen is a way of working. You often find a few individuals, departments or teams given the responsibility of implementing Kaizen projects, whilst the rest of the business by and large carries on as BAU.

The Japanese culture is aligned with this way of thinking, especially after it’s destruction in World War ll and I suppose it’s easier to create this culture within companies when it closely matches the external culture of society at large.

I enjoyed reading this article. During my Kaizen tour in Japan it was easy to see how their every day work was influenced by Kaizen. Continuous improvement is a way of life there. Most companies require Kaizen training to fix their employees and ultimately get disappointed when they do not see any significant results. Kaizen requires total participation from both employees and management in order for the system to work effectively and yield desired impact. Just like Christopher mentioned one needs to align such an initiative with company strategic objectives.

I want to know all about kaizen.