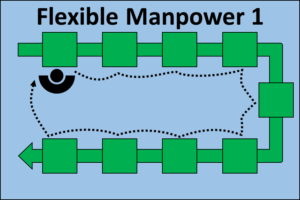

Production lines with manual labor often have the possibility of adjusting manpower due to demand. Such flexible manpower lines can work with different staff numbers, and can adjust the production output to the customer demand. At Toyota, such lines are also called Shoujinka (少人化, literally “few people production”). A gender neutral term would be “flexible staffing line”. This blog post will go into the details on how to set up such a line.

Production lines with manual labor often have the possibility of adjusting manpower due to demand. Such flexible manpower lines can work with different staff numbers, and can adjust the production output to the customer demand. At Toyota, such lines are also called Shoujinka (少人化, literally “few people production”). A gender neutral term would be “flexible staffing line”. This blog post will go into the details on how to set up such a line.

When to Use

Flexible manpower lines can be used when customer demand is changing over time. Hence the customer demand fluctuates. As I explained in a previous post, there are three fundamental ways to decouple fluctuations: You can buffer through inventory, you can let your customer wait, or you can adjust capacity. The flexible manpower line adjusts capacity. By adding and reducing the number of workers in the line, you can increase or decrease the production output. This is best used if the customer demand changes for a longer duration. Short-term changes may be decoupled simply by using inventory buffers.

Flexible manpower lines can be used when customer demand is changing over time. Hence the customer demand fluctuates. As I explained in a previous post, there are three fundamental ways to decouple fluctuations: You can buffer through inventory, you can let your customer wait, or you can adjust capacity. The flexible manpower line adjusts capacity. By adding and reducing the number of workers in the line, you can increase or decrease the production output. This is best used if the customer demand changes for a longer duration. Short-term changes may be decoupled simply by using inventory buffers.

Requirements

A flexible manpower line is not always possible. There are a couple of requirements for this to work.

Approach is for a flow shop: Such a flexible manpower line makes sense only if you have a flow shop. If you have a job shop or project shop instead, then of course you can also adjust the manpower in these production systems. However, the method is different and often requires less fine-tuning. In job shops, people often move between stations due to the needs of the system, and the structure for assigning people to stations is usually able to handle different numbers of workers anyway. Furthermore, each process in a job shop is usually a single process and the number of operators for a single process cannot be changed easily. A project shop is usually also able to handle different numbers of workers. Hence, it is usually easier for job shops and project shops to add or remove workers to adjust capacity than it is for a flow shop. Yet, flow shops are usually vastly more efficient and produce higher quality at lower cost than comparable job shops or project shops.

It must include manual work: Only with manual work can an operator move between stations and handle more than one station at a time. If you have a fully automatic system, then it is not possible to increase or decrease output during the same work time. Okay, technically you could change your machines to a slower setting, but there is no benefit in this. The machines would work slower, but you would not have any benefits from it. Rather, you risk running into quality issues because the slower speed settings may require additional fine-tuning.

It must include manual work: Only with manual work can an operator move between stations and handle more than one station at a time. If you have a fully automatic system, then it is not possible to increase or decrease output during the same work time. Okay, technically you could change your machines to a slower setting, but there is no benefit in this. The machines would work slower, but you would not have any benefits from it. Rather, you risk running into quality issues because the slower speed settings may require additional fine-tuning.

It must be more than one manual process: This is also a must-have. If your system has only one manual process, then you cannot add workers into it (of course, you could remove the single worker, but then you would not produce anything).

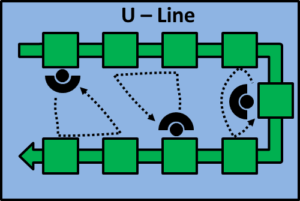

Manual stations should be close to each other: Strictly speaking, this is not an absolute must-have, but it is highly recommended. Since a worker may be covering multiple workstations, he must walk between these stations. This walking requires time, which is of course paid work time. If there are excessive walking distances, then the additional labor cost for walking is prohibitive. Often, the line layout is optimized for such flexible manpower, as for example in an U-Line or a S-Line.

Manual stations should be close to each other: Strictly speaking, this is not an absolute must-have, but it is highly recommended. Since a worker may be covering multiple workstations, he must walk between these stations. This walking requires time, which is of course paid work time. If there are excessive walking distances, then the additional labor cost for walking is prohibitive. Often, the line layout is optimized for such flexible manpower, as for example in an U-Line or a S-Line.

Labor must be flexible: If you sometimes need more workers and sometimes less, then you need to be able to adjust the number of workers. Hence, you need some flexibility with your workforce. You may be able to distribute excess workers to different flexible manpower lines with higher demand, or draw workers from flexible manpower lines with lower demand. You may be able to have more people take a day off, or ask them to come in. In sum, this approach makes sense only if you can decrease or increase the number of hours of your workforce – but please do this in a way aligned with the workers, the unions, and the local laws.

Advantages and Disadvantages

Many people believe that a flexible manpower line exists to reduce labor cost. This is not true. You could also simply reduce labor cost by reducing work time. If you have eight people working one hour or one person working eight makes no difference for your labor cost.

Many people believe that a flexible manpower line exists to reduce labor cost. This is not true. You could also simply reduce labor cost by reducing work time. If you have eight people working one hour or one person working eight makes no difference for your labor cost.

The big advantage of flexible manpower lines is leveling! While the total working time is roughly the same, the big advantage is a more continuous and steady production. This applies to the supply, to the demand, and also to the workers.

Let’s start with the workers since this is most obvious. Mathematically, it makes no difference if one worker works eight hours or eight workers each work one hour. However, for the worker it makes a lot of difference if they come to work for a normal eight-hour day or if they are called in for one hour and then sent home. The workers would be quite unhappy to commute to work only to find out that they are sent home after an hour. In any civilized country, the unions would be really upset, and rightfully so. The worker would probably prefer to take a day off rather than coming in for one hour. Hence, such a flexible manpower line is easier on the working hours of the operators.

Similarly for the supply and demand. A continuous and steady demand of parts from preceding processes is better than a line that runs at full capacity for two hours and is then switched off for the rest of the day. The same applies to the customer side – which may be the end customer or only the next production system in the value stream. No matter if suppliers or customers, if the line goes from full capacity to zero and back, you need inventory to buffer these fluctuations, and hence you need space to store it, tie up capital, increase your lead time, increase material handling, and many, many other negative aspects associated with inventory. See my post on the The Hidden and Not-So-Hidden Costs of Inventory for more. So, in sum, the advantage of a flexible manpower line is that it levels your production and keeps your inventory down, as well as allowing easier work times for the operators.

All of this does not come free, however. There are also quite a few downsides. A flexible manpower line is more management overhead. Management needs to create and maintain multiple work standards for a line with different numbers of operators. Management needs to think about which person does what if there are two, three, four, or more operators in the line. This is additional work in setting up the line. Additionally, there is the task of assigning workers to the line, other lines, or keeping them at home, although you may have similar scheduling work if you decide to run the line at full capacity with less hours instead.

The workers also have more walking distance. Since they now cover multiple stations, they have to walk between these stations. This walking distance takes time, and hence costs the company money. In some cases, the worker may be able to do a job while walking and holding a part, but this is rare.

Finally, if you reduce the number of workers, a worker needs to cover more stations. Hence, your workers need to be trained in more stations. It is actually good to have workers trained in multiple stations, and maybe you have qualified your workers already. However, if you have not yet, then this is one additional task on your to-do list.

This is the first post in a four-post series on flexible manpower lines. In the next post I have a bit more introduction before I present an example line that will be adapted for different numbers of operates using the standard work sheets from Toyota. Until then, stay tuned, and go out and organize your industry!

.A fine example of the Flexible Manpower Line outside the Toyota organisation is in the fast food industry; it is the Subway Group of sandwich shops. Go-see for yourself. You will see a one piece flow mixed model line, with every product piece customised to each individual customer’s requirements within the routine product flow The line can adjust within two minutes to changing customer demand rate (Takt Time) and adjust labour level to suit. When you compare Subway to a traditional sandwich shop with its stock of finished sandwiches based on sales forecasts, batch manufacturing and limited customer choice, you can understand why they have been so successful; a great example of the power of TPS when used as a marketing tool. What is often missed about the Toyota story is the fact that in parallel with the development of TPs, they were also growing their sales volumes. TPS was designed to support this growth.

The key point of the system and the key to its success is that it goes back to the basics of the Just in Time element of TPS. This is to give the customer, exactly what they want, giving the choices they require, in the quantity they want, when they want it. I think these four simple rules have been lost in the development of lean thinking.

The ideal future (difficult to achieve) state, is;

One piece flow, with process sequence placed in the order of product production and synchronised process times. The flow rate must match customer demand rate – Takt Time. The U shaped line gives maximum labour flexibility for different demand rates. You can see this system being applied on YouTube under Sid’s Heroes.

Hi Sid, very nice example! I have to get a sandwich from them again sometimes.

Flexible Manufacturing lines have always been the curiosity of manufacturing professionals. It’s need is ever increasing with the increase in variety of products and their customisation.

Flexible Manufacturing can also be achieved in a machining environment provided you have general purpose machines. Different machining set ups can be combined on a single / limited machines and excess machining centres can be released. This will reduce the operating cost as well as the overheads. Moreover, the released machines can be taken up for upgradation / repair work, etc.

Hi Chris,

I guess there is a little mistake in that sentence: “Yet, flow shops are usually vastly more efficient and produce higher quality at lower cost than comparable job shops or flow shops.” – you surely mean “comparable job shops or project shops” 😉

Hi Vyacheslav, thanks for spotting that. Fixed! 🙂