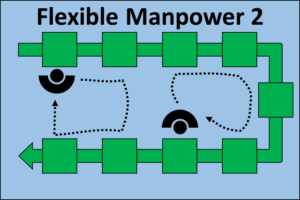

Having a flexible manpower line is a good way to adjust the production capacity to changing demand while still keeping your system leveled. In this second post in my series on flexible manpower lines, I give you some alternatives before going into more details of an example line that we will set up for different numbers of operators in the next few posts.

Having a flexible manpower line is a good way to adjust the production capacity to changing demand while still keeping your system leveled. In this second post in my series on flexible manpower lines, I give you some alternatives before going into more details of an example line that we will set up for different numbers of operators in the next few posts.

Alternative Options

A flexible manpower line is one answer to fluctuating customer demand (or, technically speaking, fluctuating supply too … but this is a whole different problem). However, it is not the only possible answer. The most desirable solution is to reduce or eliminate the customer fluctuation and force your customer to just take as much as you produce … but this is rarely an option. You may be able to influence your customer a bit, however, like the ski pole company that promoted Nordic Walking, or through promotions and special discounts.

A flexible manpower line is one answer to fluctuating customer demand (or, technically speaking, fluctuating supply too … but this is a whole different problem). However, it is not the only possible answer. The most desirable solution is to reduce or eliminate the customer fluctuation and force your customer to just take as much as you produce … but this is rarely an option. You may be able to influence your customer a bit, however, like the ski pole company that promoted Nordic Walking, or through promotions and special discounts.

Other than that, there are three fundamental ways to decouple fluctuations: Inventory, capacity, and time. The flexible manpower line adjusts capacity while running full time. You can also adjust capacity by reducing or increasing the working time of your line. This comes with the challenge of where to put the workers. Ideally, you have other tasks that need to be done, and can assign these workers to these other tasks. Sending people home earlier or later may also be possible, but this has to align with the workers and unions and labor laws. In most countries, some flexibility is possible, especially if it is announced beforehand.

Other than that, there are three fundamental ways to decouple fluctuations: Inventory, capacity, and time. The flexible manpower line adjusts capacity while running full time. You can also adjust capacity by reducing or increasing the working time of your line. This comes with the challenge of where to put the workers. Ideally, you have other tasks that need to be done, and can assign these workers to these other tasks. Sending people home earlier or later may also be possible, but this has to align with the workers and unions and labor laws. In most countries, some flexibility is possible, especially if it is announced beforehand.

If you run your line for shorter durations, you need to buffer the fluctuations through inventory, which causes more handling, storage, tied-up capital, and other costs. For shorter-term customer fluctuations, you can use inventory buffers to decouple the customer fluctuations. Finally, if all else fails, you can let the customer wait (i.e., sell less). This is usually not a desired solution but the automatic default if you were unable to resolve the issue in another way.

Customer Takt and Line Takt

The goal of a flexible manpower line is to match the customer takt with the line takt while keeping the line working during usual working hours rather than stopping the line. Quick recap: the takt is the average time between parts, and can be calculated for the customer (average time between the demand for one part) and the production (average time between the production of one part). Ideally, these two numbers are very close to each other. Please do not confuse the takt time with the cycle time. The cycle time has no problems or losses and is an ideal state. The takt time includes all losses like machine breakdowns, missing parts, defect parts, and so on. If you divide the cycle time by the takt time, you get the OEE. For more, see my post on the Different Ways to Measure Production Speed.

The goal of a flexible manpower line is to match the customer takt with the line takt while keeping the line working during usual working hours rather than stopping the line. Quick recap: the takt is the average time between parts, and can be calculated for the customer (average time between the demand for one part) and the production (average time between the production of one part). Ideally, these two numbers are very close to each other. Please do not confuse the takt time with the cycle time. The cycle time has no problems or losses and is an ideal state. The takt time includes all losses like machine breakdowns, missing parts, defect parts, and so on. If you divide the cycle time by the takt time, you get the OEE. For more, see my post on the Different Ways to Measure Production Speed.

Manpower Options and Limitations

Next you have to think about the different manpower options. For many lines this is simple. At most you can have one person per station. The smallest number would be one person for the entire line. However, in some cases there may be additional considerations. For example, some processes may need two (or even more) people to work. If you have to install a large and heavy item, the station may require two (or even more) people to lift the item into place and assemble it.

Similarly, there may be situations where having a worker at every station may be overkill. For example, assume there are two adjacent stations where a worker has to put a part in the machine, press a button, and then wait for fifty seconds for the machine to finish the process. In this case, it would be overkill to have one worker at each station spending most of its work time waiting, while one worker could easily do both jobs without any reduction in productivity.

Flexible Manpower Example

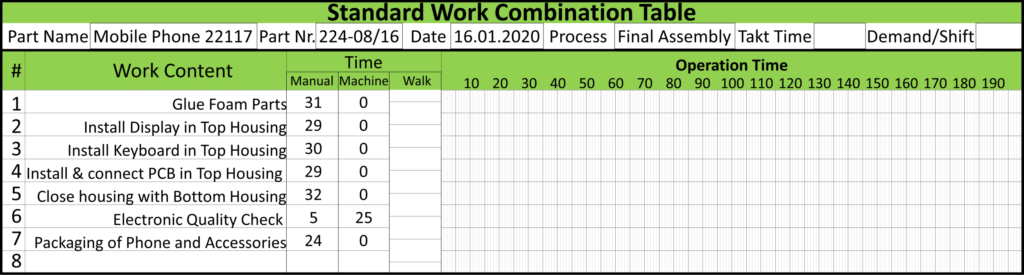

In the following, I will use a simple example of a fictional mobile phone final assembly line. There are a total of seven steps as shown below. All of them are manual work except step 6, the electronic quality check. The worker merely inserts the phone into the machine and lets the machine work on its own.

In the following, I will use a simple example of a fictional mobile phone final assembly line. There are a total of seven steps as shown below. All of them are manual work except step 6, the electronic quality check. The worker merely inserts the phone into the machine and lets the machine work on its own.

- Glue foam parts

- Install display in top housing

- Install keyboard in top housing

- Install & connect PCB in top housing

- Close housing with bottom housing

- Electronic quality check

- Packaging of phone and accessories

Standard Work Sheet

Creating a flexible manpower line is an excellent use of the standard work sheet from Toyota. Hence here we will use the standard work sheets as used by Toyota. I have written a whole series of posts on this, please check out Toyota Standard Work Part 1: Production Capacity, Part 2: Standard Work Combination Table, and Part 3: Standard Work Layout.

As you may remember, there are three parts to the standard work sheet. The first one is production capacity. Without going through all the details, here is the production capacity sheet for our example. We can see that all steps take around thirty seconds, except the step 6 quality check, where the manual labor is only five seconds and the machine takes twenty-five seconds.

Another part of the standard work sheet is the layout. Since we assume that we already have a line that we want to adapt for flexible manpower, we assume that we already have a layout. Usually, even though the number of workers in the line changes, the layout does not. Moving around the machines would take too much effort, and hence is usually not done. However, I also have seen lines where the machines were all on wheels and with flexible pneumatic, electric, and electronic connectors, and they could be moved around easily. Yet, for this example we stick to a fixed layout so as not to make things too complicated. You can find all the machines there again, and the major material supplies. This is not yet a finished layout, as we are missing the walking distances.

Another part of the standard work sheet is the layout. Since we assume that we already have a line that we want to adapt for flexible manpower, we assume that we already have a layout. Usually, even though the number of workers in the line changes, the layout does not. Moving around the machines would take too much effort, and hence is usually not done. However, I also have seen lines where the machines were all on wheels and with flexible pneumatic, electric, and electronic connectors, and they could be moved around easily. Yet, for this example we stick to a fixed layout so as not to make things too complicated. You can find all the machines there again, and the major material supplies. This is not yet a finished layout, as we are missing the walking distances.

Finally we have the standard work combination table. In this table we will check the work content (including walking and waiting) for the operators. Below is an incomplete table. It lists only the tasks and the manual and machine times. The walking times are not included, and neither is the graph for the operation time (since both depend on the number of operators).

Just as a reminder, below is the legend for the operation time that we will fill out in a bit. Black boxes are working times for operators, squiggly lines represents walking, dashed lines are the working time of machines without operators. Empty boxes represent waiting time and at the end is a vertical line representing the takt.

In my next post we will actually plan this line for different numbers of operators. We will do all options between a single operator and a sensible maximum of six operators. However, not all of these options make sense. Until then, stay tuned, and go out and organize your industry!

In TPS the purpose of standard work is to define the number of operators for a given Takt- Time. It also defines the work sequence for each operator & the standard WIP (work in process) to make the work-flow. With source inspection & Poka -Yoke devices we can then guarantee 0 defects. We have then achieved the 3 A’s, Quality Assurance, Cost Assurance (Labour, material & machinery) & Delivery Assurance (TT). All these cost and values are now controlled at the point of occurrence, not after the event in the accounts or other departments. I think these are points often missed about standard work.

Hello Christoph,

First at all thanks for your posts they are very interesting.

I am working in pharma industry(moisturizing creams, hands sanitizer and so fourth. We have 11 U shape lines. Each line has between 4-7 automated stations of wich 7 the last station is completely manual (packaging station). Actually we are doing time studies, therbling and operations analysis to improve the throughput.

What it would be your recommendations in this case to increase cycle time? What kind of lean tools we could use in this kind of lines?

Thanks for your help

Hi Rene, your goal is not to increase cycle time, but to increase output. Cycle time is only one aspect thereof (and if so, you should DEcrease cycle time 🙂 ) Try starting with an OEE. Where do you lose your capacity? Do you have breakdowns? Are your machines slower than they are? How is the defect rate?. I would alsolook at these. If you decide to go with cycle time (a completely valid approach) you first would need to find out which process(es!) are slowing you down. For this I recommend the bottleneck walk. Keep in mind that it may also be a secondary/logistic process that usually nobody looks at. You will find plenty of posts on OEE and Bottleneck walk on my blog. Hope this helps 🙂