Boeing is a well-known maker of large commercial aircraft. If you fly occasionally, you almost certainly have been on one of their planes. Lately, however, Boeing is better known for quality issues and crashed planes. It seems that management at Boeing skimped on quality to save cost and make deadlines. In this post I want to look closer at the management of Boeing, especially in relation to the safety of the Boeing 737 MAX 8. Besides using different news sources, this article is mostly based on the book Flying Blind by Peter Robinson (source below).

Boeing is a well-known maker of large commercial aircraft. If you fly occasionally, you almost certainly have been on one of their planes. Lately, however, Boeing is better known for quality issues and crashed planes. It seems that management at Boeing skimped on quality to save cost and make deadlines. In this post I want to look closer at the management of Boeing, especially in relation to the safety of the Boeing 737 MAX 8. Besides using different news sources, this article is mostly based on the book Flying Blind by Peter Robinson (source below).

Boeing 737 MAX 8 Crashes

In 2018 and 2019, two rather new Boeing planes (both shown here) of the type 737 MAX 8 crashed under very similar circumstances. Lion Air flight 610 crashed on October 29, 2018, near Jakarta shortly after take-off. Ethiopian Airlines Flight 302 crashed on March 10, 2019, in Ethiopia. Both planes reported some sort of control problem before the planes took a nose dive straight into the ground. All 346 people died; there were no survivors. Other pilots also reported similar problems with the MAX 8 planes.

In 2018 and 2019, two rather new Boeing planes (both shown here) of the type 737 MAX 8 crashed under very similar circumstances. Lion Air flight 610 crashed on October 29, 2018, near Jakarta shortly after take-off. Ethiopian Airlines Flight 302 crashed on March 10, 2019, in Ethiopia. Both planes reported some sort of control problem before the planes took a nose dive straight into the ground. All 346 people died; there were no survivors. Other pilots also reported similar problems with the MAX 8 planes.

As a result, many aviation authorities grounded this type of aircraft shortly after the Ethiopian crash, until the cause of the accident was better understood (with the US Federal Aviation Administration FAA noticeably lagging behind). Other pilots reported near misses due to similar problems with the same model of aircraft.

As a result, many aviation authorities grounded this type of aircraft shortly after the Ethiopian crash, until the cause of the accident was better understood (with the US Federal Aviation Administration FAA noticeably lagging behind). Other pilots reported near misses due to similar problems with the same model of aircraft.

By March 18, 2019, all 387 Boeing 737 MAX 8 planes in 59 airlines were grounded, plus another 400 or so newly manufactured ones were awaiting delivery. Only after twenty months, at the end of 2020, did the first aircraft of this type start to fly again.

A Bit of Boeing Company History

Boeing had an excellent reputation with regard to safety. There was a saying “If it ain’t Boeing, I ain’t going.” The company was run by engineers, and safety was a high priority. The entire Boeing culture revolved around building excellent planes. Quality and safety issues reported upward were taken very seriously, and managers spent a lot of time on the production floor.

Boeing had an excellent reputation with regard to safety. There was a saying “If it ain’t Boeing, I ain’t going.” The company was run by engineers, and safety was a high priority. The entire Boeing culture revolved around building excellent planes. Quality and safety issues reported upward were taken very seriously, and managers spent a lot of time on the production floor.

This changed in 1997 when Boeing merged with McDonnell Douglas. McDonnell Douglas was a very different type of aircraft company, run not by engineers but by accountants. The bottom line was most important. Despite that, McDonnell Douglas was struggling. Robinson writes that the merger probably saved McDonnell Douglas from bankruptcy. It was said that “McDonnell Douglas bought Boeing with Boeing’s money.” After the merger, the two management styles collided. Boeing management had been described as “boy scouts,” whereas McDonnell Douglas managers were called “hunter-killer assassins.” Hence, it did not take long before Boeing was run mostly by former McDonnell Douglas managers.

And with that, the entire culture of Boeing changed. There are reports of people being pressured NOT to report quality and safety issues. It seems people who did got fired. Making the deadline and saving cost had the highest priority. Safety was not even mentioned in the annual proxy statements between 2010 and 2014. In 2010 Airbus launched the A320 NEO family of planes, which was a direct competitor to the Boeing 737. Boeing managers were under pressure to design a new plane to compete with Airbus. Designing a completely new plane would have been quite expensive, and may have required re-licensing of the pilots, hence Boeing decided to update the 737.

A Bit of Boeing 737 Design History

The first version of the Boeing 737, the Boeing 737-100, had its maiden flight in 1967, fifty-five years ago. Since then, many upgraded versions of the plane have been developed, with the current fourth generation being the 737 MAX series, including the MAX 8. Over time, fuel efficiency became more important to the airlines. Newer, more fuel efficient engines are often larger than older engines. But this was a problem for the Boeing 737.

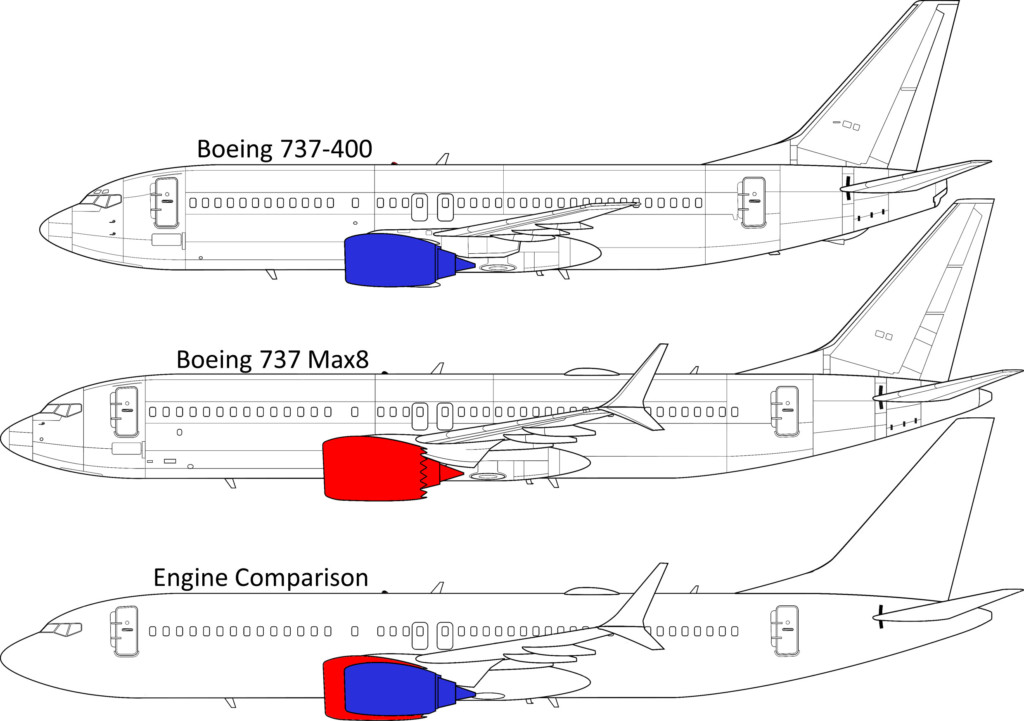

While the original turbines of the 737-100 were almost completely under the wing, the increasingly larger engines of the successor models no longer had enough space under the wings. To fit these larger and more fuel-efficient engines, Boeing moved them forward and up. Below is a drawing of the second generation 737-400 and the latest generation 737 MAX 8, with the engine highlighted in color. You can clearly see how the engine became larger and moved forward and upward. To save space, the MAX 8 engine is also somewhat flatter at the bottom when seen from the front. The engines of the third generation were somewhere in between the second and fourth generation shown here.

Some people had already commented that the fifty-five-year-old airframe had reached the end of its life, and a new design would have been better. The increasingly forward and upward position of the engine increased the risk of an unintended upward pitch in certain conditions (i.e., the plane starts to climb). To prevent this, a Maneuvering Characteristics Augmentation System (MCAS) software was added for the Boeing 737 MAX 8. This software detects if the plane has an unintentional climb, and would counteract this by steering the plane back downward.

It does this by collecting data from the plane, including its angle of attack sensor. This angle of attack sensor is a small wing at the sides of the cockpit that always stays with the airflow as shown in the (simplified) animation here. These angle of attack sensors are somewhat sensitive, and anything from a bird strike to a Mylar balloon can throw them off. Hence, there are usually at least two sensors, one on each side of the cockpit.

For some reason (Cost? Deadlines?), Boeing decided that the MCAS system would use data only from ONE angle of attack sensor. And this is a big NO-NO in aviation. Planes are built around redundancy. The failure of a single device must not cause problems, and redundancy is required to keep the plane airborne and safe. The MAX 8 did not have this redundancy, and a failure of this single angle of attack sensor would throw off the entire MCAS system. And this is what happened. The angle of attack sensor malfunctioned, and the MCAS believed that the plane was in an unintentional climb, overrode the pilot decision, and steered the plane back down toward horizontal… except due to the malfunctioning sensor it was not horizontal but downward. A lot downward! Both planes flew straight into the ground despite the pilots’ best efforts.

Another part of the problem was that the Lion Air pilots did not know of the MCAS, nor did other pilots of the MAX 8. The handbook mentioned the MCAS, but only in the appendix, and only explaining the abbreviation. The pilots were never trained on the MCAS and – crucially – how to turn it off. When designing the plane, Boeing promised that pilots would not need any additional training for the MAX 8 if they were certified for the predecessor model. Yet, adding a new software module would require additional training, especially if the module (like the MCAS) could override the pilots’ decision in controlling the plane. Hence, the MCAS was kept under wraps and the pilots did not know about the system. This shocked a lot of pilots when it came out, and further undermined trust in Boeing.

After the first crash, pilots learned about the system, and the Ethiopian Airlines pilots actually were able to turn it off. Unfortunately, they needed to turn it off within the first 10 seconds of it malfunctioning, which would be extremely fast and nearly impossible to do if the pilot first had to identify the problem and figure out what to do. By the time the Ethiopian Airlines pilots turned it off, they were already in an unrecoverable dive.

As with most accidents, they could have been prevented. But the fault, in my opinion, does not lie with the pilots, but with the design, which in turn seems to be caused by neglecting safety in favor of profit and meeting deadlines. As one person said, “Boeing got away with murder.”

The Role of the Federal Aviation Administration (FAA)

The FAA would be the oversight body to prevent makes of aircraft and other aviation companies from prioritizing profit over safety. Unfortunately, there was a lot of pressure on the FAA to make the plane happen and to look the other way. In fact, the FAA rewarded its employees if they made an airline more profitable, and they publicly shamed inspectors that caused trouble for the airlines. An FAA boss even told his people that their bonus depended on Boeing making its deadlines. Boeing was deep inside the FAA. The FAA was a “tombstone agency,” acting only if someone died. Anyhow, it seems that after two crashes, the FAA is tightening its certification process.

The FAA would be the oversight body to prevent makes of aircraft and other aviation companies from prioritizing profit over safety. Unfortunately, there was a lot of pressure on the FAA to make the plane happen and to look the other way. In fact, the FAA rewarded its employees if they made an airline more profitable, and they publicly shamed inspectors that caused trouble for the airlines. An FAA boss even told his people that their bonus depended on Boeing making its deadlines. Boeing was deep inside the FAA. The FAA was a “tombstone agency,” acting only if someone died. Anyhow, it seems that after two crashes, the FAA is tightening its certification process.

Is This an Isolated Incident?

It does not seem so. Certainly, these two crashes were the most dramatic accidents. But another plane, the Boeing 787 Dreamliner (maiden flight 2009), also made headlines with lithium-ion batteries catching fire. The problem is supposedly fixed, and no plane crashed. There were also reports on quality problems in building planes, from metal chips around wires to forgotten tools inside of planes. The latest model, the MAX 10 (a longer version of the MAX 8), is also rushed. Of particular concern is the end of 2022, after which new cockpit safety features are required by the FAA for aircraft models. It seems the MAX 10 may miss this deadline, and may require a different cockpit… which in turn would require more pilot training and increase cost even more. At the time of this writing, Boeing lobbyists are working hard to get another extension beyond the FAA deadline.

So, there seem to be lots of management shenanigans impacting the quality of the products at Boeing. Would I still fly in a Boeing? Yes, since air travel is still one of the safest forms of travel, even on a Boeing. However, if I have the option, I would prefer an Airbus. One side note, it seems that due to the power of unions in Europe, employees can speak much more openly and raise safety issues easier at Airbus than at Boeing. Anyway, this blog post turned out to be much longer than I planned, but I hope it was interesting to you. Now, go out, travel safely, and organize your industry!

PS: The day before I published this article, another Boeing 737 crashed. China Eastern Airlines Flight 5735 plunged almost straight into the ground. There were no survivors, all 132 people on board died. This was a Boeing 737-800, from the previous generation of 737’s before the Max8, and it did not have a MCAS system. The cause of the crash is still unknown. Investigations are ongoing. The airline grounded its fleet of 737-800’s for now.

Sources

Besides many articles in different newspapers, I especially recommend two sources, a book and a movie. The book provides an especially good look at the behavior of Boeing management.

- Robison, Peter. 2021. Flying Blind: The 737 MAX Tragedy and the Fall of Boeing. New York: Doubleday.

- Downfall: The Case against Boeing. Netflix documentary from 2022. Directed by Rory Kennedy

Excellent article Christoph,

This case illustrates very well the impact of taking short cuts in quality like removing redundancy.

It also shows the difficulty of validating software due to the huge amount of lines of code any product has.

Dear Chris – this is an excellent article where you have highlighted two key issues – one -about how critical quality is for a company to maintain is credibility. In the airline industry -this is non-negotiable. If the takeover of Boeing by McDonnell Douglas moved the ‘management attention’away from quality – then that is tragedic and speaks volumes about the existing culture in Boeing

And that reminds of what the Guru -Peter Drucker had to say about ‘Culture eating Strategy for breakfast’ every day .

In India where I live – one of the largest emerging markets for passenger aircraft – Airbus is the overwhelming leader with Boeing a distant # 2.

lets hope Boeing learns its lessons and brings its focus back to quality and safety

What a great article. The biggest takeaway for me was the merger that occurred with Boeing and McDonnell Douglas. This merger changed the culture of the company and changed the want from high quality and efficiency to be taken over by the bottom line. A strong culture, regardless of the industry is imperative to success. The biggest flaw other than falling to the pressures of deadlines was training the pilots on MCAs. Education is key to creating an environment that promotes synergy, it also helps prevent injuries or deaths as sadly happened in a few Boeing occasions.

Thank you for the article Professor Roser. This is an interesting (and tragic) tale of “When Two Cultures Collide”. You suggest that the cost cutting culture won out over the quality culture, but this is not necessarily a given. It would be interesting to dig a little deeper to better understand why cost cutting won out over quality in this instance. I suspect there would be a few lessons learnt from such an analysis.

If memory serves, a motivator for Boeing’s purchase of MacDac (the term used in Boeing for McDonnell Douglas) for their lucrative government space business. Companies fail for reasons endemic to the organization. When you pick up one end of a stick, you pick up the other end. A merger (the stick) brings in the good and the bad. Unfortunately leadership can be so blinded by the good, they can’t or won’t see the bad.

Need to into deep and deep how management did drove the projects, the sick organisations are deputing commercial consultants to save money.

Just like most real-life situations, the whole 737 MAX (nose down) story is complicated and there are multiple issues at hand.

For one, MAX absolutely had to be a “drop-in” replacement for existing planes in service. This was a non-negotiable requirement from the customers. All of the big airlines have their operations structured so that crews can be moved from aircraft to aircraft without issue. Introducing a new aircraft type into the mix completely breaks the process for the airlines (training pilots on the new plane and certifications, maintenance, etc…). Ditto the same for airports that may or may not have the equipment to serve a new aircraft type. Not to defend Boeing, but their hands were mostly tied on that one. And yes, MCAS was put in as a kludgy workaround for the fact that the engines’ size and placement significantly changed the plane’s handling.

As for training, there’s a split in the pilot community on this one. I’ve read a good number of accounts on Quora from airline pilots all of whom say that the wheels indicating trim are very visible inside the cockpit and that disabling MCAS is a pretty straightforward and quick process. More importantly the runaway trim checklist (aviation equivalent of standard work) contains the instructions to disable MCAS and explicitly states that once the MCAS is disabled, it is to remain disabled for the remainder of the flight. So a lot of pilots do blame the pilots and the airline for not training them enough on the updated inflight emergency checklists. Unfortunately, that’s the way it goes in a lot of real-life operations. Too often, they try to get by with the least amount of training expenses they can get away with.

Don’t quote me on this, but I’ve heard the whole design decision where MCAS relies on only a single AoA sensor had to do with costs as well. Just like with cars made in 90s and early 00s, there’s the bare bones base model, and then there are all the add-on options that only some customers will want to pay for. Remember the days when things like power windows and ABS were options rather than standard equipment? Same thing here. The airframe had to be modular enough to accomodate customer wishes from western airlines and all the way down to the “fiscally challenged” operators in places like Ethiopea

Hi Andrey, yes, there were external constraints on Boeing (training and compatibility with previous 737’s), but in my opinion they took way more shortcuts than sensible. Designing a crucial system based on a single and often malfunctioning sensor is in my view more than just negligence.

Also for the training, initially pilots were NOT trained on this, only after the first plane crashed. Besides, the situation can become non-recoverable in less than 10 seconds. Quickly: Change your car from normal to Eco driving mode in 10 seconds, or you will all die…

I am driving my car since 14 years, and I would have to search the button.

I thought this article was very insightful. I was in my MBA program during the MAX crashes. Specifically I was in Business law. My professor got to do a deep dive into these cases and how Boeing lobbyist work. Not a great system we operate here in the U.S. At the very least training should have been done. That blows my mind. Oh and the fact that there was no redundancy set up.

Sad about the New crash on the China flight.

I know they use air travel as an example of Six sigma but seems like that stat needs some rework…

This was certainly a wonderful read and on a topic I was not that familiar with. I’d heard of the Boeing 787 Dreamliner issues with their lithium-ion batteries causing fires, but I hadn’t heard of these crashes in the 787 Max8s. It seems the merger and management have completely changed Boeing, once a safety and quality industry leader is now struggling to get by as they are more focused on cutting costs and meeting deadlines. I’d read the issues with Dreamliner aircrafts were due to extensive outsourcing of parts, that Boeing lost all control. Not to mention, while trying to cut costs outsourcing, they were frequently sent parts that did not fit the quality or design they needed for their aircrafts, which lead to more costs and issues. The FAA certainly isn’t doing them any favors by allowing them to cut corners, people’s lives are at risk and that should be their main concern. But these events definitely highlight how important management and values of a company are, as they can make or break a company.

Enjoyed reading your comments. I wrote this last year, after a good long time going thru Boeing annual reports. https://dollarsandsense.org/archives/2021/0721duggan.html

This article is a tribute to how American companies get away with murder by paying some money, Then they escaped criminal charges as well. This truly sucks & the worst part about it is that their families will never die like that because they can afford to fly quality planes and not the trash they fly us around in. We as a people should strike the airlines & refuse to use any Boeing planes. We need to start taking back control of our country from big business.

Just watched an “Air Accident Investigation” program about a MacDonald Douglas aircraft that crashed – was found to be a door design fault that the management knew about before selling the aircraft – it was responsible for hundreds of deaths. Mac Donald got a huge fine for it – eventually the company went bust, and was bought out by Boeing – the Same managers then ‘took over’ Boeing…

Christoph,

Good read, Harry Stonecipher and Phil Condit were ueseful ID10T’s masterminding the merger. Both companies were managed by bean counters. in St. Louis we just wanted John McDonnell gone, that only got worse. The last Engineer that ran MACAIR was Bill Ross. After that there was a pathway to destruction, MCAIR was cash heavy, Boeing was going broke. $16B was infused into Boeing to keep them afloat. The 737 has had several issues prior to the merger, the rudder actuator on the early jets was one. The work horse of the single isle jets was the DC-9, it was a hotrod in the air especially with the JT-8’s. This discussion is important.

Thank you!!!