Yet another hot topic in lean manufacturing is visual management. This can be very helpful in running a shop floor, but when done wrong it can also be quite wasteful and embarrassing. In this post I would like to show you the basic principles of visual management with a few examples. There is more to visual management than merely putting lines on the shop floor.

Yet another hot topic in lean manufacturing is visual management. This can be very helpful in running a shop floor, but when done wrong it can also be quite wasteful and embarrassing. In this post I would like to show you the basic principles of visual management with a few examples. There is more to visual management than merely putting lines on the shop floor.

Practical Tips

Hands on, practical tips that you can use for your work immediately. Academic theory is reduced to a minimum

How to Ramp Up a Kanban System – Part 2: The Switch

In my last post I described how to prepare for the implementation of a kanban system. This post goes into more detail on the actual change to the new kanban system. You surely know that every part should have a kanban. But what do you do if you have more kanban than parts? What do you do if you have more parts than kanbans? Find the answers below.

In my last post I described how to prepare for the implementation of a kanban system. This post goes into more detail on the actual change to the new kanban system. You surely know that every part should have a kanban. But what do you do if you have more kanban than parts? What do you do if you have more parts than kanbans? Find the answers below.

How to Ramp Up a Kanban System – Part 1: Preparation

Designing a kanban system on paper is much easier than implementing it on the shop floor. In many of my previous posts I discussed the design of a kanban system in detail. In these two posts I will discuss the steps needed to actually put the system on the ground. This first post is the preparation, and my next post will be the actual switch to the new kanban system.

Designing a kanban system on paper is much easier than implementing it on the shop floor. In many of my previous posts I discussed the design of a kanban system in detail. In these two posts I will discuss the steps needed to actually put the system on the ground. This first post is the preparation, and my next post will be the actual switch to the new kanban system.

Kanban Card Design

A kanban is, in its basics, information to reproduce or reorder parts. Hence, in its most basic form it has to say “make me this part” or “bring me this part.” While such very simple kanban systems are possible, usually it helps to include other information on the kanban card. In this post I want to talk about the design details of a kanban card, especially what kind of information we should include on the card. Please note that the items on the list below are suggestions. Which ones you actually include depend on the system you want to establish.

A kanban is, in its basics, information to reproduce or reorder parts. Hence, in its most basic form it has to say “make me this part” or “bring me this part.” While such very simple kanban systems are possible, usually it helps to include other information on the kanban card. In this post I want to talk about the design details of a kanban card, especially what kind of information we should include on the card. Please note that the items on the list below are suggestions. Which ones you actually include depend on the system you want to establish.

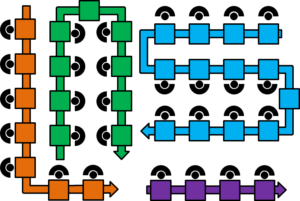

Line Layout Strategies – Part 2: I-, U-, S-, and L-Lines

The layout of a line can make quite a difference in the performance of your line. The U-line is most famous, although in my view while good it may not be the right thing for all situations. There is also the I-line, the S-line, and the U-line. In my last post I described some general thoughts on line design and took a look at the big picture. In this post I want to look at and compare actual line layouts, in particularly the I, U, S, and L layout. Let me give you an overview of the different options.

The layout of a line can make quite a difference in the performance of your line. The U-line is most famous, although in my view while good it may not be the right thing for all situations. There is also the I-line, the S-line, and the U-line. In my last post I described some general thoughts on line design and took a look at the big picture. In this post I want to look at and compare actual line layouts, in particularly the I, U, S, and L layout. Let me give you an overview of the different options.

Line Layout Strategies – Part 1: The Big Picture

In flow shops, you have a production line of some sort. This may be an assembly line or a manufacturing line; this may be automatic or manual. In lean, you often hear about the famous U-line.

In flow shops, you have a production line of some sort. This may be an assembly line or a manufacturing line; this may be automatic or manual. In lean, you often hear about the famous U-line.

While this is a great solution, it may not fit all problems. Depending on the surrounding conditions, a different line layout may be beneficial. This post is the first in a series on line layout. In this post I would like to discuss what you should consider when designing a new line layout. The next post will look at actual line layout options.

On the Benefits of a Pencil in Lean

In many lean books and other writing, it is often recommended to use a pencil for certain tasks as, for example, the A3 report. Yet, I have seen very few uses of pencil in lean manufacturing in the Western world. Most of the documents are computer printouts based on Excel, PowerPoint, or Word. The few handwritten documents are usually done in pen (see also my post on The Advantage of Handwritten Data on the Shop Floor).

In this post I will look into why almost nobody uses pencils and why it would be good to use more pencils. I myself am also guilty of that, but I plan indeed to use more pencil in the future.