In this second post of my series on point-of-use providers (also known as Mizusumashi, water strider, or water spider), I will discuss the calculation of the workload for the point-of-use provider … although calculation is a way-too-big word for what is, in practice, guesswork with limited data of low quality. However, I hope it helps you with planning your point-of-use providers.

In this second post of my series on point-of-use providers (also known as Mizusumashi, water strider, or water spider), I will discuss the calculation of the workload for the point-of-use provider … although calculation is a way-too-big word for what is, in practice, guesswork with limited data of low quality. However, I hope it helps you with planning your point-of-use providers.

Calculating the Workload

Calculating … or, more likely, estimating the work load of the point-of-use provider depends very much on the situation you have in your factory. How much material does he have to carry, how heavy it is, how long are the walking distances, what kind of tools (pallet jack, forklift, etc.) does he need, how big are the buffer inventories at the line, how long do they last, and so on.

Estimate the Duration of the Route

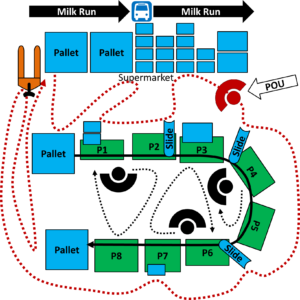

Your goal is to make sure that the point-of-use provider can refill any material on the line before it runs out. For this you would need to sum up the time the point-of-use provider needs to refill all of the material. This is best done with a detailed layout of the line showing all the required stops, including the required quantities, the demand, and the inventory sizes and reach at the stations.

Your goal is to make sure that the point-of-use provider can refill any material on the line before it runs out. For this you would need to sum up the time the point-of-use provider needs to refill all of the material. This is best done with a detailed layout of the line showing all the required stops, including the required quantities, the demand, and the inventory sizes and reach at the stations.

Sum up time for walking distances, handling time, and other tasks like kitting and repacking. Do not forget the way back to the starting point and trips to pick up a pallet jack, etc. Also keep an eye out for how much he has to carry. You get the time the point-of-use provider needs for his loop.

Compare with the Material Quantities

This time needed to supply all stations needs to be compared to the inventory at the stations. Is there enough inventory (plus safety) to last until the point-of-use provider comes back? If the time for the route matches the inventory reach well, then you have a well-balanced route for the point-of-use provider. However, this is unlikely to happen in the first iteration of your calculations.

This time needed to supply all stations needs to be compared to the inventory at the stations. Is there enough inventory (plus safety) to last until the point-of-use provider comes back? If the time for the route matches the inventory reach well, then you have a well-balanced route for the point-of-use provider. However, this is unlikely to happen in the first iteration of your calculations.

If there is additional time for the point-of-use provider, how much time does he have left? Maybe he can do some additional tasks (more on this below)?

If there is not enough time, then you have a problem. The point-of-use provider has too much work and will be unable to supply your line with enough material. Now you have multiple options.

You could increase the buffer inventory at the stations and the quantity of material that the point-of-use provider is carrying. He does not come more often, but he brings more stuff. However, if you find that he now has to carry 80 kg on his route, you have another problem. He won’t be able to do this. Even with less weight, carrying multiple packages and boxes at the same time is cumbersome and risks dropping items. A pushcart could make it easier. Rather than carrying items, he would put them on his cart and just push them along. Just make sure that this does not get too heavy, as he won’t be able to push half a ton along the line safely or reliably. Now you could up the ante even more and give him a small material train, but this is absurd for short distances. Besides, you would need a lot of space at the stations to store all this material. Eventually you may need a second (or even more) point-of-use providers.

Optimize

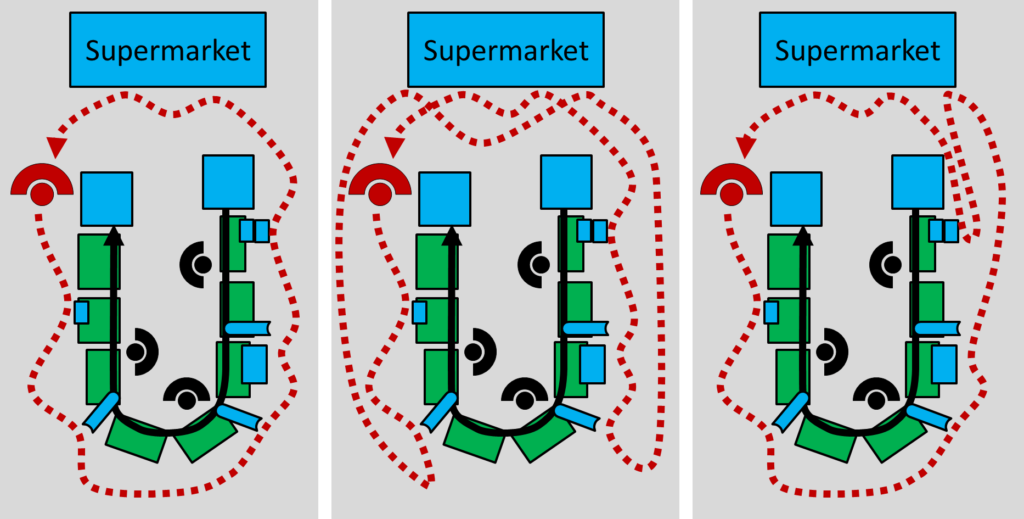

But before you get additional point-of-use providers, see if you can optimize his workload. Can you simplify handling tasks? Can they be automated or mechanized (see karakuri kaizen)? Could he do a short trip for nearby stations and then a longer one for farther-away stations? Or could he do one trip for the left side and then one trip for the right side of the station? The whole process is iterative. You try out different routes; calculate the time, material reach, and weight; and see if it works. I also suggest that instead of optimizing one solution until it fits, you should try multiple independent solutions and see which one is the best (see my post on Japanese Multidimensional Problem Solving).

Worst-Case Scenario?

Do not estimate this for the average situation, but lean toward a worst-case scenario! For example, while the point-of-use provider may have enough time to supply each material after another, he may run into problems if two different locations run out of material at the same time!

At the same time, you do not need to include the absolutely worst-possible scenario. First of all, you will never be able to afford a cover for every eventuality. Second, a point-of-use provider is a human, and he can and (hopefully) will speed up in times of need. Hence, he may be able to defuse temporary and short-term overloads by putting in an extra effort. However, if the point-of-use provider has to run all the time, he soon will run out of energy, motivation, and (understandably) morale, and the line will suffer. Therefore, such moments where he has to work “on the double” should be rare and exceptional, as this would be an overburden (muri).

At the same time, you do not need to include the absolutely worst-possible scenario. First of all, you will never be able to afford a cover for every eventuality. Second, a point-of-use provider is a human, and he can and (hopefully) will speed up in times of need. Hence, he may be able to defuse temporary and short-term overloads by putting in an extra effort. However, if the point-of-use provider has to run all the time, he soon will run out of energy, motivation, and (understandably) morale, and the line will suffer. Therefore, such moments where he has to work “on the double” should be rare and exceptional, as this would be an overburden (muri).

Overall, it is difficult to calculate, but you have to make an estimate if you create a new line or change an existing one. Include a point-of-use provider that has experience with similar situations and has a good “gut feeling” on these things.

How About Side Jobs?

![]() Ideally, the point-of-use provider is fully occupied with his tasks, having no idle periods while always supplying the line with material. In reality, however, he may have a bit of slack or available time. Since these waiting times are waste (muda), it may be tempting to fill up this available time with additional work.

Ideally, the point-of-use provider is fully occupied with his tasks, having no idle periods while always supplying the line with material. In reality, however, he may have a bit of slack or available time. Since these waiting times are waste (muda), it may be tempting to fill up this available time with additional work.

It can be done, but be very careful with this. As I said above, the primary objective of the point-of-use provider is to keep the workers supplied with material. Hence, any additional work should be work that can be dropped at any time to take care of the material supply. If the additional work would be time critical (e.g., an assembly process where others would have to wait), then sooner or later the point-of-use provider is needed both for the critical add-on work AND the material supply. No matter what he does, others will have to wait for him, and that is no good. Again, the primary objective of the point-of-use provider is to keep the workers supplied with material!

However, if you take care, side jobs are possible. Here are a few examples:

- Often the point-of-use provider also helps the workers in case of problems and is the first responder if there are issues to resolve. For example, if the milk run made a mistake, the point-of-use provider can try to get needed material from the warehouse.

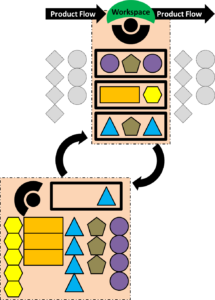

Another task that is common for a point-of-use provider is kitting.

Another task that is common for a point-of-use provider is kitting.- The point-of-use provider can also be part of the assembly-line process. However, in this case he still must be able to interrupt his work to supply material to everybody. His work in the line should be much less, and it must be buffered with inventory so that an absence from assembly in order to supply material does not stop the line.

- Irregular tasks that can wait can also be added to the point of use provider, like packing finished goods or returning empty packaging like cardboard to the recycling station (nearby!)

This concludes the second post of this three-post series on point-of-use providers. In my previous post I explained the basics of point-of-use providers. My next post will go into details on the routing of point-of-use providers. I hope you will enjoy it :). Now, go out, get your material flowing, and organize your industry!

This problem is present in every workload calculation in a warehouse. It is a put away case, whose behaviour is that of a reverse picking in dispatch orders. A previous analysis of the demand in terms of handling units is the beginning. The key is to let the figures talk; they lead to the most suitable working methods. The time required, obviously, comes out from multiplying the number of units involved in each operation times their standard time.

If you have a simple process that has a lot of overcapacity compared to other processes in the factory the point-of-use provider can have this as a side job.

A process that only needs 4 to 6 hours (per 24 hours) can be a side job for a three shift team of providers. A kanban system let’s the providers do the planning on their own.

Bom dia. Estas postagens são muito boas , estão sendo muito úteis para me evoluir como profissional.

Ich danke Ihnen und bis zu nächstem Post 🙂