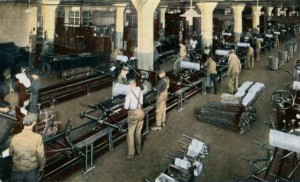

I am a strong believer in the advantage of flow shops. To me, job shops are an inherently chaotic system. While there are ways to manage job shops, these are merely (more or less) successful attempts to put a Band-Aid on the chaos. To me, only a conversion to a flow shop will bring underlying stability. In this post I would like to give you both historic and current examples of successful conversions from a job shop to a flow shop.

I am a strong believer in the advantage of flow shops. To me, job shops are an inherently chaotic system. While there are ways to manage job shops, these are merely (more or less) successful attempts to put a Band-Aid on the chaos. To me, only a conversion to a flow shop will bring underlying stability. In this post I would like to give you both historic and current examples of successful conversions from a job shop to a flow shop.

Flow Shop

Performance Comparison of Job Shop and Flow Shop

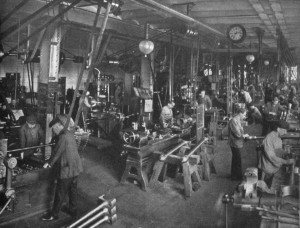

Job shops are, in their nature, much more chaotic than flow shops. Previously, I have written a lot on this topic. In this post I would like to take a deeper and quantitative look at this effect. Using simulations, we take two systems and try to make them as identical as possible – except that one is a flow shop and the other is a job shop. This blog post is based on a thesis by my student Daniel Ballach.

Job shops are, in their nature, much more chaotic than flow shops. Previously, I have written a lot on this topic. In this post I would like to take a deeper and quantitative look at this effect. Using simulations, we take two systems and try to make them as identical as possible – except that one is a flow shop and the other is a job shop. This blog post is based on a thesis by my student Daniel Ballach.

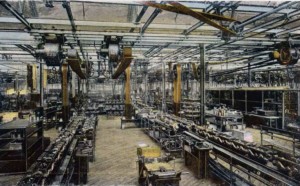

How to Convert a Job Shop into a Flow Shop – Part 2

How to Convert a Job Shop into a Flow Shop – Part 1

Job shops are always very difficult to manage. As I described in my previous posts, the irregular material flow causes fluctuations that are very hard to contain. In my view, the only true fix for a job shop is to convert it into a flow shop. In this post I will talk a little bit about how you approach the idea of converting a job shop into a flow shop … although this is not always possible. However, in many cases it is possible to increase flow-shop-like segments, even though the whole system is still a job shop.