In my previous posts I talked a lot about internal milk runs. However, you can also have milk runs externally across multiple suppliers and plants. There are a few things to consider that are different from the internal milk runs. Let me elaborate …

In my previous posts I talked a lot about internal milk runs. However, you can also have milk runs externally across multiple suppliers and plants. There are a few things to consider that are different from the internal milk runs. Let me elaborate …

Introduction

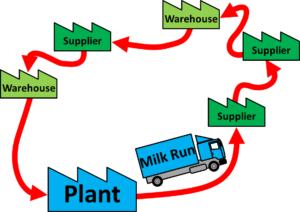

External milk runs transport goods from different suppliers or warehouses to the destination. They use trucks and drive on regular public roads. Hence the main difference is that they are subject to traffic conditions.

In fine weather during off-peak hours, the truck may be able to do the cycle in two hours. However, during rush hour in a snowstorm, the time can easily multiply. Therefore, two major differences between in-house and external milk runs are weather and traffic conditions.

Your milk-run cycle calculations should not be based on ideal conditions. Rush hours are jammed and weather may change, yet you still want your plant to be up and running. Hence you should do the calculations with a sufficient safety buffer by assuming some congestion or bad weather for your milk-run cycle time. On the other hand, if you plan your milk run to work even during the snowstorm of the century, you may be overdoing it with your safety.

Your milk-run cycle calculations should not be based on ideal conditions. Rush hours are jammed and weather may change, yet you still want your plant to be up and running. Hence you should do the calculations with a sufficient safety buffer by assuming some congestion or bad weather for your milk-run cycle time. On the other hand, if you plan your milk run to work even during the snowstorm of the century, you may be overdoing it with your safety.

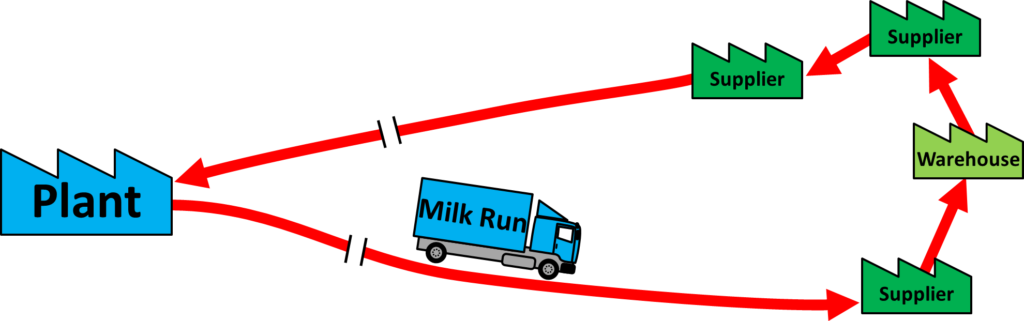

Another difference is that internal milk runs usually pick up material at one site and drop it off at multiple locations within the plant. For external milk runs it is usually just the opposite. The truck picks up material at different locations (warehouses or plants) and brings it to one central location (also a plant or a warehouse).

Basics

An external milk run works best if all the stops for picking up material are near the destination. As a rule of thumb, it is recommended that the milk run should be able to do its route in less than two or three hours. Hence, they cannot make too many stops, and another rule of thumb recommends no more than five stops to pick up material.

An external milk run works best if all the stops for picking up material are near the destination. As a rule of thumb, it is recommended that the milk run should be able to do its route in less than two or three hours. Hence, they cannot make too many stops, and another rule of thumb recommends no more than five stops to pick up material.

Calculation Difference to Internal Milk Runs

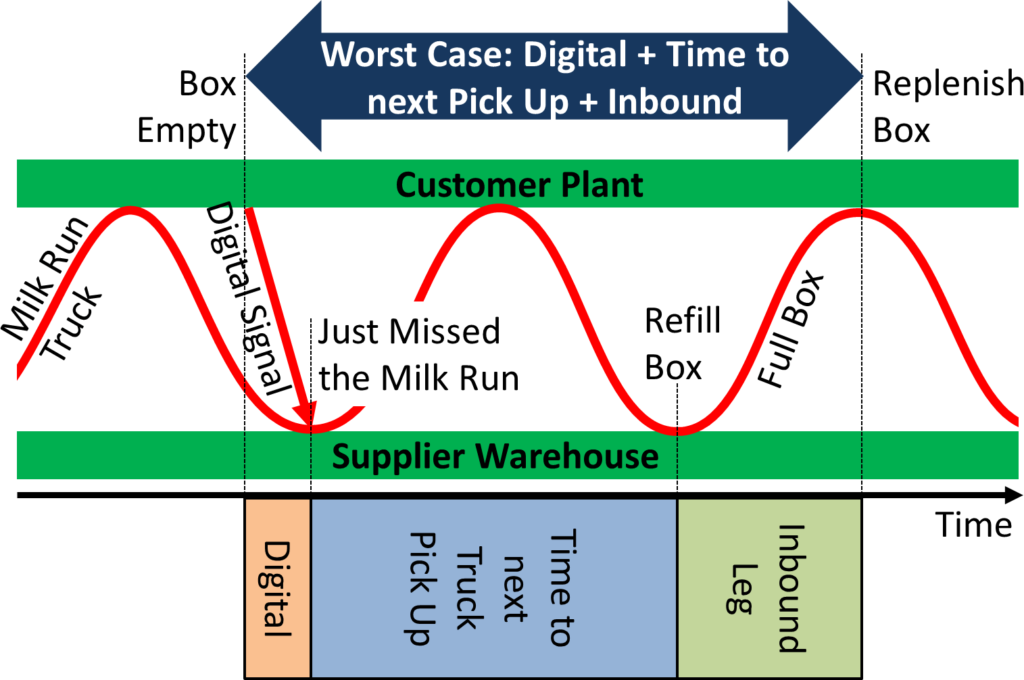

The calculation for external milk runs can be done quite similar to the calculation of internal milk runs. You need enough material to cover the duration until the milk run returns. There is, however, one major difference: In internal milk runs, the signal to replenish is an empty box arriving at the warehouse. In external milk runs, it is very common to create a digital signal (e.g. through your ERP system). The replenishment time does no longer include the time for the truck to drive out, but hopefully the much faster time of collecting the data and sending the digital information.

While the digital data travels at near-light-speed, do not neglect the time to collect and process the data. However, it is likely to be faster than a truck driving out. Hence the time that needs to be covered with material in the milk run consists of the items below. This is also visualized in the diagram below.

- The time for the data signal of an empty box to arrive at the supplier warehouse

- The maximum time the supplier has to wait for the next milk run truck to arrive at the supplier (including loading of the material)

- The time for the milk run to drive back from the supplier to the destination (including unloading and bringing it to the destination supermarket).

Truck Types

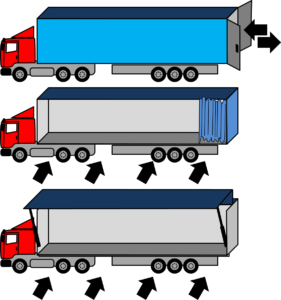

The most common type of trucks have a door at the rear. This is easiest to build, but allows loading and unloading only through a small area in the back. If you need to get a certain material (or in our case, more likely an empty box or pallet for refilling), you may have to remove everything else from the truck.

The most common type of trucks have a door at the rear. This is easiest to build, but allows loading and unloading only through a small area in the back. If you need to get a certain material (or in our case, more likely an empty box or pallet for refilling), you may have to remove everything else from the truck.

Hence, for milk runs it may be better to have trucks than can be loaded from the side. This could be by sliding back a plane, or by flipping the entire side of the truck up for easy access. These “gullwing trucks” are very common in Japan, but I have been told that European regulations for securing loads handicaps their use in Europe.

Having access from the side allows a more selective unloading. For the typical milk run, this makes it easier to return custom containers to the plant or warehouse where they are refilled. It also makes it much easier to maintain Just in Sequence deliveries.

The size of the truck is also relevant. A common habit of logistics is to get the biggest truck and fill it up to the max so the transport costs are reduced. However, this would increase the required buffer inventories, and smaller trucks that run more frequently may be better overall.

Long-Distance Suppliers

There may be situations where the material is coming from a long-distance source. In this case you have two options (based on Lean Logistics: The Nuts and Bolts of Delivering Materials and Goods by Michel Baudin).

Remote Suppliers to Local Warehouse

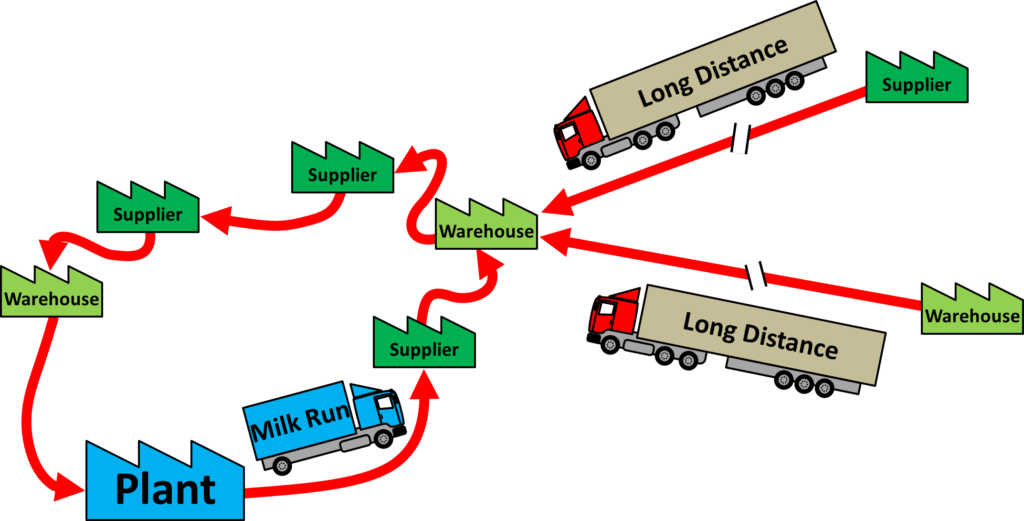

The sources farther away could deliver to a warehouse closer to the destination. Regular trucking brings material from far-away suppliers or warehouses to a local warehouse. The local warehouse contains a buffer stock (based on the replenishment time from the far away suppliers). The milk run simply picks up the material from the warehouse buffer. However, you can also consider having the long-distance trucks deliver directly to your plant warehouse, and you in-house milk run takes over the rest.

Remote Supplier Cluster

If there are multiple suppliers together in a remote cluster, you can also have a milk run into a warehouse (or cross dock) at the supplier cluster, and then haul the goods from the warehouse to your plant using long distance trucking.

Long-Distance Milk Run

Finally, you can also have a long-distance milk run, stopping at different suppliers and warehouses. However, the longer the milk run, the longer the milk-run cycle. And, as we have seen in my previous posts Calculating the Material for your Milk Run, the milk-run cycle is one of the key factors determining the required material buffers. A milk-run cycle that takes, for example, two days instead of two hours does need twenty-four times the buffer inventory for twenty-four-hour round-the-clock assembly, or eight times if you work only one shift per day.

You could use multiple trucks on the same loop, but they will not proportionally reduce the inventory. Multiple trucks reduce the time the information has to wait until the next truck as described in the diagram above at “Calculation Differences”. See also my post on Frequently Asked Questions for Milk Runs for details.

Another issue to worry about with long driving distances is the required rest periods for the drivers. If your travel time alone takes twenty hours, the driver will need a ten-plus-hour rest in between (depending on the laws in your location).

If your suppliers and customers are close to each other, you could even combine inbound milk runs with outbound milk runs. Just make sure that if you return empty packaging to your suppliers or customers there is still enough space for the actual goods.

These are a few options for long-distance milk runs. There are more variations possible. You have to find out what works best for your plant.

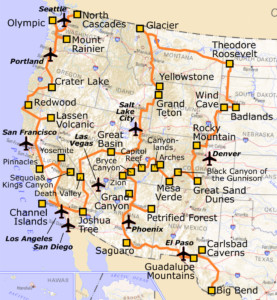

The Traveling Salesman

If you have multiple stops on your milk-run route, there are a number of different sequences in which you can visit them. This is commonly known as the traveling salesman problem, an exciting mathematical problem.

If you have multiple stops on your milk-run route, there are a number of different sequences in which you can visit them. This is commonly known as the traveling salesman problem, an exciting mathematical problem.

Mathematically optimal solutions are available for routes exceeding 1,000 stops, and if your milk run has 1,000+ stops, then you are doing something else wrong! Hence for your typical milk run with five stops or less, the problem can be solved reasonably easy.

There is only one thing to consider: Do you optimize for shortest travel distance or shortest travel time? I strongly recommend travel time, since in your plant time is much more valuable than a truck driving thirty miles more.

So this is an introduction into external milk runs, supplying material from other plants or warehouses. Keep in mind, however, that milk runs make sense only for parts that you consume regularly in larger quantities, and that you have a buffer stock. If it is an on-off part, a milk run is the wrong tool. Similarly, if you consume so much of it that the milk run is almost always full with parts from only one supplier, a direct haulage may be better. You could see this as a milk run with only one stop (on top of your own plant). Now, go out, get your material flowing, and organize your industry!

Selected Sources

A good book discussing external milk run (and other things) is by Michel Baudin (and all of his writing is worth reading): Baudin, Michel. 2005. Lean Logistics: The Nuts and Bolts of Delivering Materials and Goods. New York, NY: Taylor & Francis Inc.

Fantastic post! Waiting for it was worth.

Great post and what is the successful factor to run external milk run ?

in china the traffic is sometime difficult-)

Glad you liked it 🙂