Milk runs are a popular concept for material delivery within a plant and even across multiple plants. It is very much based on the philosophy of pull, keeping inventories down, and making material supply easier.

Milk runs are a popular concept for material delivery within a plant and even across multiple plants. It is very much based on the philosophy of pull, keeping inventories down, and making material supply easier.

However, it is only suitable for mass-produced goods, or more precisely for identical components and identical parts, even if they go into different product variants. Additionally it can also be used with kitting. This post starts a series on the topic of milk run with an introduction to the topic.

The Original Milk Run

Milk runs were originally just what the name implies, a person delivering milk to different households along a route. This was a common approach in the United States, Great Britain, the Netherlands, India, and other places to distribute milk. However, due to the nature of the product, this type of delivery differed significantly from, for example, the delivery of mail or other goods.

Milk runs were originally just what the name implies, a person delivering milk to different households along a route. This was a common approach in the United States, Great Britain, the Netherlands, India, and other places to distribute milk. However, due to the nature of the product, this type of delivery differed significantly from, for example, the delivery of mail or other goods.

Fresh milk is a product that perishes quickly. With modern refrigeration it can last a bit longer. Pasteurized milk (common in Germany, for example) can even be kept for months without refrigeration. However, nowadays raw milk still is the biggest cause of hospitalization due to foodborne diseases. The short shelf life of milk was an even bigger problem before modern refrigeration and pasteurization. It was difficult to have a stockpile of milk, and milk had to be consumed quickly before it spoiled.

Therefore the milk men and women used a few simple tricks to help their customer. Along their route, they simply replaced empty milk bottles with full bottles. If the customer put one empty bottle out for the milk man in the morning, he got one full bottle. If the customer put out two empty bottles, he got two full bottles back (and so on). Hence, this empty bottle was not only for reuse and recycling, but also contained a signal to replenish the consumed milk. In modern lean lingo, this milk bottle would be a kanban! More precisely it would be a transport kanban, since the milk man did not produce the milk but merely transported it from a storage facility. Such “box” kanban are also common nowadays.

Therefore the milk men and women used a few simple tricks to help their customer. Along their route, they simply replaced empty milk bottles with full bottles. If the customer put one empty bottle out for the milk man in the morning, he got one full bottle. If the customer put out two empty bottles, he got two full bottles back (and so on). Hence, this empty bottle was not only for reuse and recycling, but also contained a signal to replenish the consumed milk. In modern lean lingo, this milk bottle would be a kanban! More precisely it would be a transport kanban, since the milk man did not produce the milk but merely transported it from a storage facility. Such “box” kanban are also common nowadays.

Through this simple approach, the milk run created a stable supply of milk to the household. Of course, things still could go wrong, and the milk could spoil if the customer was away, or the customer could run out of milk if he needed more than average. But for most days the basic supply was provided with a minimum amount of fuss and hassle.

Update: Actually, Michel Baudin says the milk run comes from combat pilot slang for an easy trip (see comment below). Juan Carlos Viela on the other hand says the milk run was the truck that collected the milk from the different farms and brought it to the processing facilities. Hence, the actual source of the name is a but fuzzy, but the milk men example above is a good example of the in house milk run, whereas the collecting truck is a good example of the external milk run which I will discuss in a later post.

The Modern In-House Logistics Milk Run

The modern logistic milk run is pretty much the same as the old milk run (except for the milk, I guess). It is a way to provide material from a central warehouse to the assembly and manufacturing lines. Like the original milk run, it replenishes consumed material on a regular schedule. Hence, it is used only for products where there is a constant need for the same material over and over again (although it can be used in connection with kitting; more on that below). There are a couple of requirements that make a logistics process into a milk run:

The modern logistic milk run is pretty much the same as the old milk run (except for the milk, I guess). It is a way to provide material from a central warehouse to the assembly and manufacturing lines. Like the original milk run, it replenishes consumed material on a regular schedule. Hence, it is used only for products where there is a constant need for the same material over and over again (although it can be used in connection with kitting; more on that below). There are a couple of requirements that make a logistics process into a milk run:

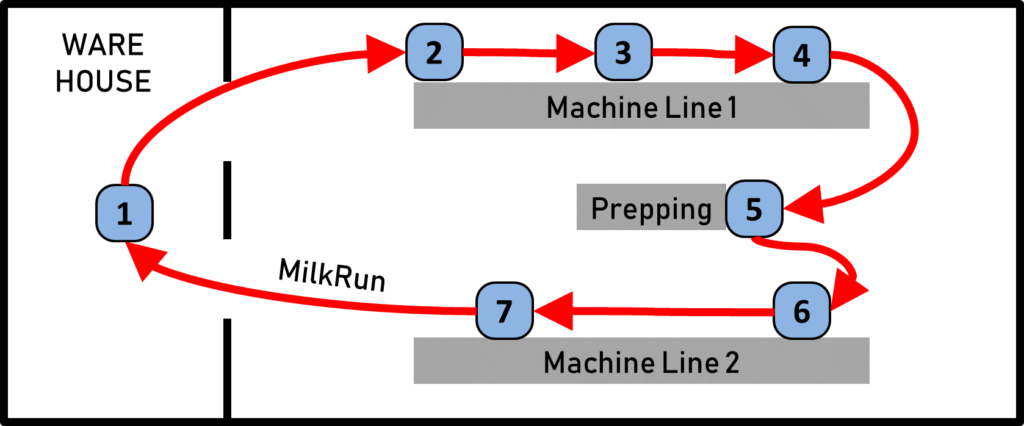

- It has a fixed route with multiple stops. The milk run originates typically in a warehouse or kitting area, moves along a fixed route with multiple stops, and at the end returns to the starting point. There are no branches or doubling back. There is a fixed number of stops along the line where the milk run removes empty boxes and provides new boxes with full material.

- The milk run runs on a fixed schedule. For example, while the plant is running, the milk run starts every hour at fifteen minutes past the hour.

- The milk run replenishes only consumed material. If there is an empty box or container, the milk run takes it away and on the next visit brings a full box of the same material. Of course, it is possible to also tag along some on-demand material that is needed only once, but this is best avoided. The normal replenishment of consumed material is easiest, and the more exceptions and additional tasks you add, the more likely something is going to get messed up eventually. Do this only if you see no other way of avoiding it.

The picture above shows an example of an in-plant milk run with a total of seven stops (including the warehouse at the beginning). These milk runs can be within the plant (in-house logistics) or on public roads connecting multiple plants or suppliers (external logistics).

Benefit of the Milk Run

The milk run gives a few benefits and follows the philosophy of lean.

The milk run gives a few benefits and follows the philosophy of lean.

- It makes an often somewhat random job (“hey, we need more stuff over here…”) into a standardized and cyclic work. The milk run follows a single, reasonable simple standard that repeats almost identically over and over again, a big improvement over the random calls for material (either by humans or by ERP systems) that are still common in many plants.

- Since it is a repetitive standard, you can have a more efficient use of your manpower. The milk-run worker will provide material to the line or remove empty boxes most of the time, whereas a traditional forklift frequently runs empty and hence wastes time and energy.

- As it is a repetitive standard, it is much easier to optimize and improve. As we will see in subsequent posts, the capacity of the milk run and its usage can be calculated reasonably well, which is harder to do for a “random” forklift.

- The milk run is part of a pull production. The boxes are the kanban that get restocked as they are consumed. There is no accumulation of inventory. There can never be more inventory than the number of boxes assigned to the system.

- This pull production will also help you to get the signal upstream to your suppliers. If the consumption is higher, the system will pull more. If the consumption is slower, the system will pull less. While you still may have to arrange with your supplier the average quantities, smaller fluctuations are easier to handle.

- Due to the milk run being a pull production, it will have less inventory than a comparable performing push system.

- This reduced inventory leads to a reduced use of space around your assembly line. And the assembly line is the spot where space is most valuable. Saving space at the assembly line is probably even more valuable to the system than simply reducing inventory. See also my post on Twelve Ways to Create Space around Your Assembly.

- Another side effect of the pull system is that the inventory – more or less – manages itself. You do not need to track when to send what to where, as this happens automatically with the milk run.

- As a final side effect, since the pull system happens more or less automatically, there is less chance for human (or computer) error, and in a properly defined system you are less likely to have stock-outs.

Drawback of the Milk Run

The milk run has one major limitation: It works only for mass-consumed parts that are in stock at the assembly line. If your assembly line needs lots of customized items, the milk run may not be the right thing for you.

The milk run has one major limitation: It works only for mass-consumed parts that are in stock at the assembly line. If your assembly line needs lots of customized items, the milk run may not be the right thing for you.

One possibility of using the milk run with customized items is by kitting, where the milk run delivers kits. However, in this case, a just in sequence approach is needed. More on this later.

The next post has much more on organizational details, before I go into the calculation and set-up of the milk run. Go out, get your material flowing like the milk of the milk men, and organize your industry!

Very nice. I grew up in UK with those milk men. We recently added a milk run design tool with the timing calls and look forward to adapting it for knitting and just in sequence.

Your lean pull explanation is clear. Only point, this is not a pull system at all but a push one: cows don’t stop producing milk because the kanban has less bottles.

Very interesting post. I’m looking forward to reading the next post about the matter.

You have not mentioned anything about milk run for collections at suppliers’. ¿Could you, please, talk about this practice? It is quite common in the automotive sector.

Hi Juan, the post is already written and will be the last one of this six-post series, being published on October 30. If you can’t wait let me know and I will send you a preview 🙂

Thanks for your answer, Christoph. I’ll be patient and wait.

A good topic to cover. You might want to trace its origin in the WW2 aircraft industry in Germany. In order to keep stocks of parts from being destroyed in allied air raids, the “ABC” system involved having trucks collecting matching sets of parts from suppliers within a few tens of kms from the aircraft assembly plant, and assembling them onto planes as quickly as possible.

As for the term “milk run,” it doesn’t actually come from milk delivery. It was airplane pilot slang for an easy flight, like a “cake walk.” The term is now standard in manufacturing but has nothing whatsoever to do with its original meaning.

Hi Michel, I did not know about the German system. You are always a treasure trove of knowledge.

I came across the term milk run also in aviation as an easy combat flight, but I thought this also originates from the milk men. Plus, the milk men “bottle kanban” fits perfectly to the modern meaning. In any case, the milk men are a wonderful explanation of the modern milk run.

I thought the milk run concept came from the milk collection at farms. The same truck performs every day the same route, stopping at the same points in the same sequence. The only different thing in that activity is the amount of collected mik (the fat percentage too) every day. Cows give more milk in summertime than in wintertime. I learn quite a lot with your comments.

Hi Juan,

… interesting. Now we have three possible sources of the name. I added an update to the post above. Thanks for the input!

I loved learning about the milk run history and how the strategy/name came into fruition. When looking at the actual process it is a great idea that keeps assembly line inventory levels low and makes sure materials are kept stocked. The biggest draw back however is that this process can only be used for mass used items, not numerous customized items. When looking at larger supply chains for example “MARS Candy Bars” this could be a great use of the system. As candy uses numerous of the sam ingredients (palm oil, sugar, etc.) this hourly system could be great. All in all this system is great at not overusing inventory and making sure that their are not shortages in supply.

The milk run is also a variant of a pull system. Supermarkets usually simply replenish what they consume.