Kanban is the best known way to establish pull production. But it is not the only way. There are many different methods to create a pull system. This blog post is loosely based on my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production, which is a practical guide for anyone looking to implement pull systems. Let me give you an overview.

Kanban is the best known way to establish pull production. But it is not the only way. There are many different methods to create a pull system. This blog post is loosely based on my new book All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production, which is a practical guide for anyone looking to implement pull systems. Let me give you an overview.

This is a Cross-Post with the (almost) identical article 7 tools to establish pull production on Planet Lean.

Introduction

There is much misconception on what a pull system actually is. Here is the definition from my book, which has three requirements.

There is much misconception on what a pull system actually is. Here is the definition from my book, which has three requirements.

- A pull system must have an explicit target limit on your inventory or workload.

- A pull system must release a signal when an item or batch of items leaves the system. For batches of material, the signal can be with either the first or the last item in a batch.

- This signal must start replenishment for make-to-stock items or release the next job for make-to-order items. The replenishment or release must be the same quantity or the same workload as the items that left the system.

- A system missing any of these three requirements above is a push system.

See also my post The (True) Difference Between Push and Pull (which is also one of my most popular blog posts). Now, let me introduce you to the many different ways to establish pull systems.

Almost Pull: FIFO

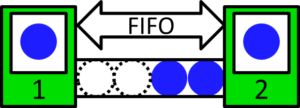

This one may surprise you, but First-In-First-Out (FIFO) is not only an excellent tool for material flow, but also a rudimentary pull system. There is a upper limit on the inventory. When a part leaves, a space opens up, which is the signal for the preceding process to fill up this space. Hence, FIFO on its own is a rudimentary pull system. The only thing missing is that while an empty slot signals the preceding process to produce, it does NOT signal what to produce.

This one may surprise you, but First-In-First-Out (FIFO) is not only an excellent tool for material flow, but also a rudimentary pull system. There is a upper limit on the inventory. When a part leaves, a space opens up, which is the signal for the preceding process to fill up this space. Hence, FIFO on its own is a rudimentary pull system. The only thing missing is that while an empty slot signals the preceding process to produce, it does NOT signal what to produce.

Hence, if you use only FIFO, you will need additional information on what to produce. In reality, however, a FIFO is part of a larger production system, and the info on what to produce is provided, often even through a pull system.

Kanban

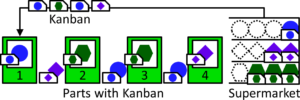

This is the best known way to establish pull production. The inventory is limited by the number of kanbans. If a part leaves the system, the kanban returns to the beginning of the loop and initiates reproduction. Effectively, the kanban is the signal. This is one of the easiest ways to implement pull, and there are even different variants of kanban systems.

This is the best known way to establish pull production. The inventory is limited by the number of kanbans. If a part leaves the system, the kanban returns to the beginning of the loop and initiates reproduction. Effectively, the kanban is the signal. This is one of the easiest ways to implement pull, and there are even different variants of kanban systems.

Production kanban and transport kanban work very similarly, except the one reproduces and the other one re-delivers. If you have only two kanban for one part type, it is often called a two-bin kanban system. One box of parts is used, and another box is replenished. A triangle kanban has only one kanban per part type, which reduces ordering effort at the cost of a slightly higher inventory.

CONWIP

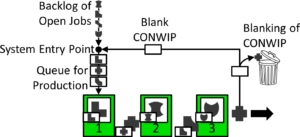

Kanban and its variants are excellent tools to establish pull production. Unfortunately, these work only for make-to-stock production, and does not work for make-to-order production. However, there is a very similar pull system that manages make-to-order production. Unfortunately, this method lacks a well-known name. The most common name is CONWIP for Constant Work in Progress, but at Toyota it is also called Type B Kanban. Many companies use such a system without ever giving it a name.

Kanban and its variants are excellent tools to establish pull production. Unfortunately, these work only for make-to-stock production, and does not work for make-to-order production. However, there is a very similar pull system that manages make-to-order production. Unfortunately, this method lacks a well-known name. The most common name is CONWIP for Constant Work in Progress, but at Toyota it is also called Type B Kanban. Many companies use such a system without ever giving it a name.

The method is very similar to kanban. However, a kanban is permanently assigned to a certain part type, and you have different kanban for different part types. CONWIP is for make-to-order production, and the CONWIP card is blanked whenever a finished job leaves the system. A returning blank CONWIP card signals to start the next job. To know which job to start, you need a (prioritized) backlog of open jobs. A returning blank CONWIP card gets attached to the next available job in the backlog. This process is called “System Entry.”

Overall, CONWIP limits the number of jobs in the system. Whenever a job leaves, a signal is given to start the next job. Hence, this, too, is a pull system, well suited for make-to-order. It can also easily be combined with kanban into a mixed kanban-CONWIP system.

POLCA

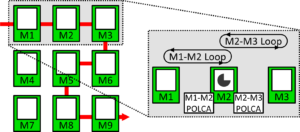

POLCA stands for “paired-cell overlapping loops of cards with authorization” and was developed by Rajan Suri around 1990. It is designed for low-volume-high-mix production and intended for job shops. It is an alternative to CONWIP. Both are possible for job shops. POLCA is a bit better in controlling the inventory, but is more cumbersome to implement and maintain. POLCA is also not designed for flow lines, but for job shops and networks of cells. CONWIP is easier to implement and maintain, but doesn’t control the inventory in a job shop as nicely.

POLCA stands for “paired-cell overlapping loops of cards with authorization” and was developed by Rajan Suri around 1990. It is designed for low-volume-high-mix production and intended for job shops. It is an alternative to CONWIP. Both are possible for job shops. POLCA is a bit better in controlling the inventory, but is more cumbersome to implement and maintain. POLCA is also not designed for flow lines, but for job shops and networks of cells. CONWIP is easier to implement and maintain, but doesn’t control the inventory in a job shop as nicely.

Reorder Point

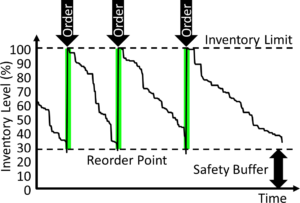

Reorder point and its closely related reorder period method for managing inventory is also a pull system. You have your target inventory and a reorder point. Whenever the inventory reaches the reorder point, you order enough material to re-fill the inventory to the target. As such it is also a pull system.

Reorder point and its closely related reorder period method for managing inventory is also a pull system. You have your target inventory and a reorder point. Whenever the inventory reaches the reorder point, you order enough material to re-fill the inventory to the target. As such it is also a pull system.

It is most commonly found in purchasing, but also sometimes in production, but always for make-to-stock or purchase-to-stock situations. Its function is very similar to the triangle kanban. I also consider this to be an excellent pull system especially for purchasing.

Drum-Buffer-Rope

Drum-Buffer-Rope (DBR) originated with Goldratt and his Theory of Constraints. It is similar to kanban or CONWIP, but with a few differences. Drum-Buffer-Rope usually measures not a quantity of parts, but a workload in the system. Such a workload control is more accurate, but requires much more effort. Hence, I avoid workload control unless my parts have enormously different workloads, and even then I may just stick with kanban or CONWIP. Besides, you can also adjust CONWIP to use workload control, resulting in a system similar to Drum-Buffer-Rope, but much better.

Drum-Buffer-Rope (DBR) originated with Goldratt and his Theory of Constraints. It is similar to kanban or CONWIP, but with a few differences. Drum-Buffer-Rope usually measures not a quantity of parts, but a workload in the system. Such a workload control is more accurate, but requires much more effort. Hence, I avoid workload control unless my parts have enormously different workloads, and even then I may just stick with kanban or CONWIP. Besides, you can also adjust CONWIP to use workload control, resulting in a system similar to Drum-Buffer-Rope, but much better.

CONWIP is better because Drum-Buffer-Rope also has the limitation that the pull loop ends at the bottleneck (or the customer). Hence, Drum-Buffer-Rope has only a single loop, which may not even cover the entire value stream. It also assumes that the bottleneck is fixed … which it rarely is. Unless you are a lover of Drum-Buffer-Rope, stay away from this.

COBACABANA (Theoretical Only)

COBACABANA, developed by Martin Land and improved by Matthias Thürer, is also a pull system. It is entirely paper based, but rather complicated, requiring many different cards for each job. In theory it is a complicated but good system, but that is just it. To my knowledge there is no real world application of this method yet. Unless you love to try out new and untested methods, I would advise against COBACABANA (and for that reason it is only in the appendix of my book).

COBACABANA, developed by Martin Land and improved by Matthias Thürer, is also a pull system. It is entirely paper based, but rather complicated, requiring many different cards for each job. In theory it is a complicated but good system, but that is just it. To my knowledge there is no real world application of this method yet. Unless you love to try out new and untested methods, I would advise against COBACABANA (and for that reason it is only in the appendix of my book).

Summary

Overall, there are a lot of different methods to establish a pull system. You probably knew kanban, and maybe even some others, but I would be surprised if you knew all of them (unless you read my book, that is). Hence, you do have more options to establish pull than you may have though. But which one is right for you? This will be the topic of my next post (and also a chapter in my book). Now, go out, use pull in your work, and organize your industry!

Series Overview

- Pull: A Way Forward for Supply Chains – Guest Post by John Shook

- The Different Ways to Establish Pull Production

- What Are the Criteria to Decide on a Pull System?

- Which Pull System Is Right for You?

- What Different Pull Systems Can Be Combined?

Source

This blog post is summarized from my latest book on pull production, where you will find many more details on all of these systems and how they can work together. You will also find a foreword by John Shook.

Roser, Christoph. All About Pull Production: Designing, Implementing, and Maintaining Kanban, CONWIP, and other Pull Systems in Lean Production. 441 pages: AllAboutLean.com Publishing 2021.

Muy interesante, donde compro el libro

Hello Jose, the book is available on Amazon Links here: https://www.allaboutlean.com/all-about-pull-production/ . A Spanish version is in translation, and will be available later this year.

[Hola José, el libro está disponible en Amazon Links aquí: https://www.allaboutlean.com/all-about-pull-production/ . Se está traduciendo una versión en español, que estará disponible a finales de este año. ]

This is a lesson in “you can learn something new every day”. I had never heard of Copacabana and thought I had read most of the available literature after being a lean practitioner for may years. We have developed another pull method for complex manufacturing environments (re-entrant, multi-workflow, and the like) in the digital era and call it Time-based Demand-pull. You can read about it here: https://www.equation1.com/

Maybe a candidate for #7 in your next edition?

Congrats Christoph on the new book! It is a fantastic compilation and tool. I have followed you for years now and am always going back to your material and referring others to it as well. You can only get so much out of “The Toyota Way”; this is real help……………

Many thanks, Scott. I hope the book will help you in your daily work doing lean 🙂

When I worked in the automotive industry, we implemented a Pull system for certain parts at the assembly line. These parts were put in two bins, holding 50 parts each. The parts in the bins were ordered in the same sequence of the cars at the assembly line. The operators at the line then took parts from the first bin. When that bin was empty, they started to take parts from the second bin. The empty bin was sent to the warehouse to get replenished again. This Two-Bin-System with sequenced parts is kind of a mix between a Supermarket pull and Sequenced Flow (FiFo-Lanes) system and we called it Sequenced Pull. The main benefit was the decreased floor space at the line needed to store the parts compared to a supermarket. Is there another name for that system?