Ship to Line (STL) is yet another technique in lean to optimize your material flow. The idea’s gist is that instead of bringing material to the warehouse, you deliver it directly to the line or to the point of consumption. Like a freshly delivered pizza, you don’t put it on the shelf and eat it two days later. However, for Ship to Line to work, there are a few things to be aware of and to take care of. Let me explain:

Ship to Line (STL) is yet another technique in lean to optimize your material flow. The idea’s gist is that instead of bringing material to the warehouse, you deliver it directly to the line or to the point of consumption. Like a freshly delivered pizza, you don’t put it on the shelf and eat it two days later. However, for Ship to Line to work, there are a few things to be aware of and to take care of. Let me explain:

The Conventional Approach

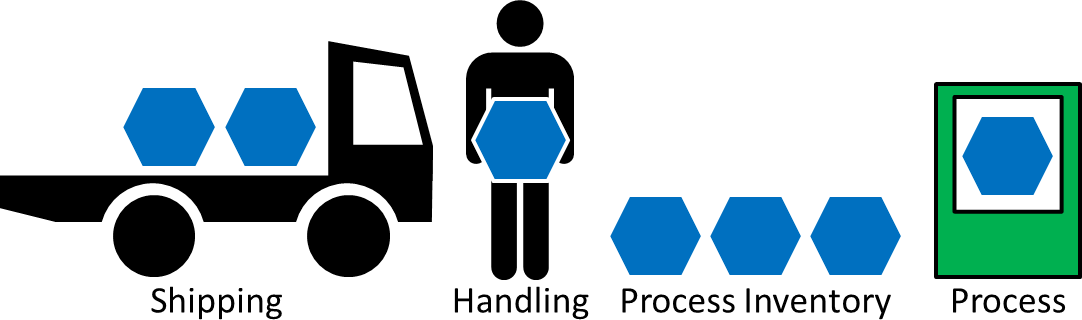

The conventional not-ship-to-line approach is for arriving material to be stored in a warehouse until it is needed for production. When needed, it is taken out of the warehouse again and brought to a usually much smaller inventory next to the production processes.

As you can easily see, the material is handled at least twice, once when it is stored in the warehouse and once when it is moved to the actual process. In reality, for organizational reasons, there are often even more handling steps included (e.g., unloading of the truck into a buffer space, and moving it from the buffer to the warehouse, then from the warehouse to a buffer again and finally to the process).

Ship to Line

Ship to Line aims to reduce these steps. Rather than storing the material in a warehouse, the material is brought directly to the point of consumption (the process) and used. Hence, one of the advantages is less material handling, which frees up worker capacity for other tasks.

The above image is a slight simplification. The “handling” above consists of different steps. The process starts with a truck of material arriving. This truck is unloaded. When unloaded, the material is usually put in a short-term storage area. At Toyota, the unloaded material is put on a small carriage that is moved to this short-term storage area.

At this short-term storage area, rather than moving the material to the warehouse, the material supply for the processes takes the material. At Toyota this is done using small electric trailer. The worker creates a small train with matching material in the right sequence, and then uses this trailer to pull the carriages to the processes. There the material is unloaded and stored directly at the process.

Prerequisite: Low Inventory

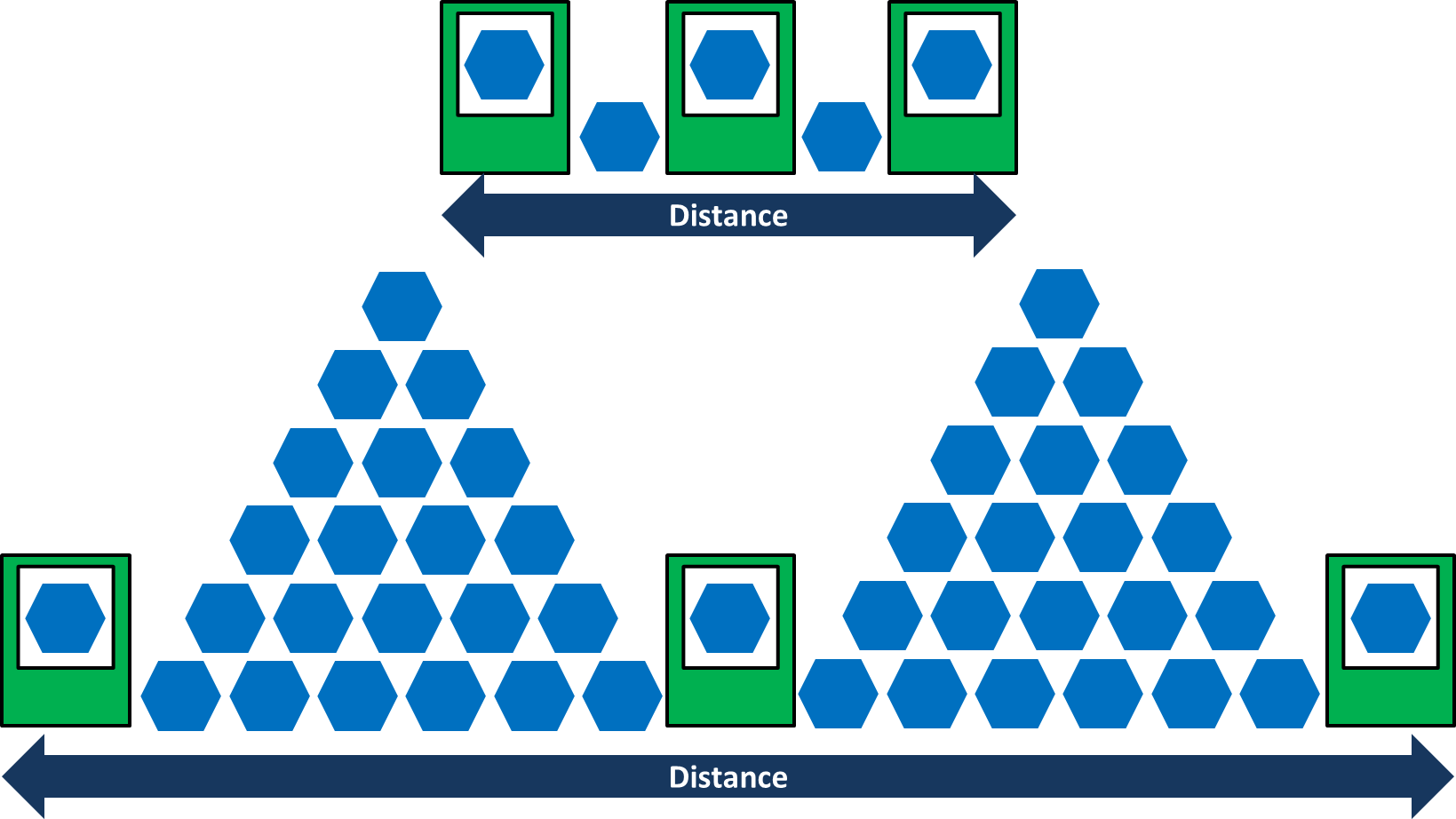

For Ship to Line to work, there are a few requirements. The biggest and most important requirement is a lean and low inventory. All the material that arrives has to be stored very close to the process. Yet, space at or around your processes is always in short supply. The closer you can move your processes together, the more efficient your production will be. Processes that are close to each other require less transport, less walking, and have a much faster information flow, especially in case of problems. Hence, there is always a shortage of storage space at the processes, as this floor space comes at a hefty premium in efficiency. This limitation in floor space causes almost all the other requirements on Ship to Line.

Subsequently, Ship to Line requires very small inventories. Any non-lean plant that has two weeks’ worth of inventory will be unable to store all the inventory at the line directly. At Toyota, they have very few hours’ worth of inventory, which they can store at the line directly.

This low inventory causes most of the other requirements. You need more frequent but smaller deliveries. If you get a big truck once per week, you cannot store it at the line. Instead, you need a smaller truck more frequently to make Ship to Line work. With so little inventory, it has to arrive only when it is needed.

Hence, Just in Time is a big prerequisite for Ship to Line. In fact, if you don’t have a (good and working) Just in Time approach, you should not be thinking about Ship to Line (unless you have extremely small parts where even two weeks’ worth of inventory does not use much space). For more on Just in Time (or JIT), see my series of posts starting with What Is “Just in Time”?.

Hence, Just in Time is a big prerequisite for Ship to Line. In fact, if you don’t have a (good and working) Just in Time approach, you should not be thinking about Ship to Line (unless you have extremely small parts where even two weeks’ worth of inventory does not use much space). For more on Just in Time (or JIT), see my series of posts starting with What Is “Just in Time”?.

As Ship to Line requires Just in Time, it does have the potential problems of Just in Time. If you change your production plan on short notice, or if you need the parts earlier or later than planned, your system will run into trouble. Hence, like Just in Time, Ship to Line is possible only for a very stable production system.

Helpful Concepts

Smaller Parts

Due to this space requirement, Ship to Line (and Just in Time) is much easier for smaller parts. Large, bulky materials need more space, and hence you can only afford an even smaller inventory. A large box of O-rings may last you quite some time, whereas the same volume of engine blocks will be used up in the blink of an eye. It can be done, but it is more difficult. On the other hand, the reward is bigger since you can reduce the more expensive materials.

Packaging Suitable for the Process

Another thing to consider is the packaging of the materials. While this is not an absolute requirement, it does help your efficiency. Ideally, the packaging the material arrives in and the packaging that is used at the line should be identical. Hence, if you use plastic boxes at the line, you should have the goods shipped in plastic boxes, not cardboard boxes. Similar for blisters and other packaging. Otherwise you have to repack the goods from one container to another container, which is a waste.

In most cases, I have seen the packaging of the supplier is adjusted to match the packaging at the line. Less commonly, the packaging at the line is changed to match the packaging of the supplier.

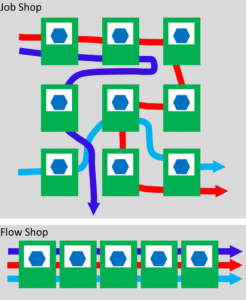

Flow Line

Yet another requirement is that your production system is a flow line. The issue with job shops is that they are much more difficult to plan, and the timing of their material demand is much harder to predict.

Yet another requirement is that your production system is a flow line. The issue with job shops is that they are much more difficult to plan, and the timing of their material demand is much harder to predict.

Flow lines are much easier to plan, and you know much better which material is needed when and where. On a side note, Ship to Line would also work with a project shop.

Just in Sequence

Ship to Line combines very well with Just in Sequence. If your parts arrive already in sequence, you have less work getting them to the line. For more on this, see my series of posts on Just in Sequence.

Advantages

The main advantage is to be able to reduce your handling of material. Rather than storing the goods in the warehouse and taking them out again, you bring them directly to the line.

A side effect is that you can then reduce your material even more, since your lead time from truck to machine no longer needs these handling steps. While some see it as a tool primarily for material reduction, I believe the material reduction comes with Just in Time and is a prerequisite for Ship to Line. Ship to Line just squeezes a little bit more water out of an already dry towel.

I hope this brief overview of Ship to Line was of interest to you. Now, go out, see if this approach would help you, or if it at least inspired you to reduce your inventory a little bit more, and organize your industry!

Hello Christopher,

first of all great post and congratulations for the 4th anniverssary of your blog. Right now I´m working at BMW and I always recommend your website for my coworkers 🙂

Now to the question:

The most lean approaches that we learn are developed for short distances between the production site and the suppliers (e.g. STL, JIT, JIS). I worked for a while in the aeronautical industry and in this case many expensive parts (e.g. hardwares) are shipped oversee and it is very hard to find suppliers closer to the production. A ship delivery takes normally 1 month to arrive and a flight cargo about 5 workdays. Which lean tools would you use to coordinate such long distance deliveries? At that time we decided for a cross-docking with a kanban system in the warehouse. What you think about this approach?

Again congratulations and please keep organizing your blog so that we can organize our industry 😀

Hi Guido, very good question. For an answer, I prepared a whole blog post that will go online soon. Cheers, Chris.