In our first post on line balancing, we looked at the tasks that must be included in the line. In this second post of this series on line balancing, we look at the durations for the individual tasks. Of particular interest are different strategies on how to balance a line if the tasks have different durations for different products. A second consideration is if the equipment is already available or is still to be purchased (and hence can be customized more). The next post will look at more details of the losses (i.e., the OEE).

In our first post on line balancing, we looked at the tasks that must be included in the line. In this second post of this series on line balancing, we look at the durations for the individual tasks. Of particular interest are different strategies on how to balance a line if the tasks have different durations for different products. A second consideration is if the equipment is already available or is still to be purchased (and hence can be customized more). The next post will look at more details of the losses (i.e., the OEE).

Shopfloor

Line Balancing Part 1 – Data Overview

Balancing the workload in a manufacturing system helps greatly in improving performance. Most importantly, it reduces unevenness (mura) due to different workloads. This in turn will reduce wasted waiting time (muda) for those with too little work, and overburden (muri) for those with too much. Additionally, I usually find it to be one of the easier aspects of lean manufacturing, since the new standard can simply be enforced through the layout of the machines. This post looks at data preparation, especially the customer takt and the list of tasks. It will be the first in a long series of posts on line balancing. The next post will look at the durations needed for the tasks.

Balancing the workload in a manufacturing system helps greatly in improving performance. Most importantly, it reduces unevenness (mura) due to different workloads. This in turn will reduce wasted waiting time (muda) for those with too little work, and overburden (muri) for those with too much. Additionally, I usually find it to be one of the easier aspects of lean manufacturing, since the new standard can simply be enforced through the layout of the machines. This post looks at data preparation, especially the customer takt and the list of tasks. It will be the first in a long series of posts on line balancing. The next post will look at the durations needed for the tasks.

Taiichi Ohno’s Chalk Circle

One of the famous teaching methods by Taiichi Ohno is the chalk circle. The method itself is simple. A circle is drawn on the shop floor near a point of interest. A disciple is put in the circle and told not to leave it until he is picked up again by the teacher.

One of the famous teaching methods by Taiichi Ohno is the chalk circle. The method itself is simple. A circle is drawn on the shop floor near a point of interest. A disciple is put in the circle and told not to leave it until he is picked up again by the teacher.

In this post I will explain a bit about the chalk circle, how to use it for teaching, and how to use it for yourself.

How to Use an Andon – and How Not To

In my last post, All About Andon, I detailed how the mechanical side of an Andon signaling system works, including Andon cords, buttons, and boards. In the Western world, the mechanical side of an Andon system usually works pretty well. However, in most cases, the usage of the Andon is poor to nonexistent. Hence, in this post I tell you how to actually work with an Andon, and then I will give you a rant why companies so often mess it up!

In my last post, All About Andon, I detailed how the mechanical side of an Andon signaling system works, including Andon cords, buttons, and boards. In the Western world, the mechanical side of an Andon system usually works pretty well. However, in most cases, the usage of the Andon is poor to nonexistent. Hence, in this post I tell you how to actually work with an Andon, and then I will give you a rant why companies so often mess it up!

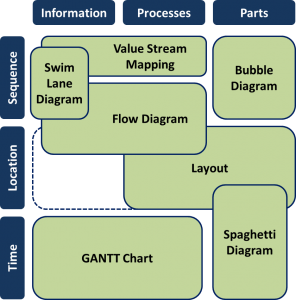

Visualize Your System – Overview of Diagrams in Manufacturing

Organizing your manufacturing system is one of the keys to success in manufacturing. There are different tools available, although I have the feeling they are often mashed together or confused. Time for a structured overview of the different manufacturing diagrams available, with recommendations. The following post does not give a full explanation on how these visualizations work. Instead, I want to give you a summary of what is out there, so you can pick the right tool to improve your system.

Organizing your manufacturing system is one of the keys to success in manufacturing. There are different tools available, although I have the feeling they are often mashed together or confused. Time for a structured overview of the different manufacturing diagrams available, with recommendations. The following post does not give a full explanation on how these visualizations work. Instead, I want to give you a summary of what is out there, so you can pick the right tool to improve your system.

How to Make 5S Stick

In my last post I detailed the 5S method (and its variants 4S, 6S, and so on). However, knowing the theory is the easy part. Successfully implementing 5S is much more difficult, and industry is ripe with anecdotes on failed 5S implementations. Here I will give you a few tips on how to increase your chances of success. However, there is no magic bullet. Cleaning and organizing a shop floor is hard work, and keeping it that way is even harder.

How 5S Works

5S is one of the basic methods in lean manufacturing, used to create and maintain a clean and organized work environment. As far as lean methods go, it looks pretty easy. After all, everybody has cleaned something at least once. Unfortunately, cleaning it once is not enough. The challenge is to keep it clean! And this is where most 5S activities fail. In this post I want to describe the basics of 5S and how it works (plus also 4S, 6S, and even more S’s). In my next post I want to point out the hidden dangers of failure, and give some advice on how to make 5S stick.

Shop Floor Etiquette – Part 2

This is the second post of a two-post series on shop floor etiquette (first post here). I find this a very necessary post, as I have way too often observed visitors to the shop floor lacking manners (and occasionally, I may have lacked manners myself 🙁 ). Hence, please do not treat this post as optional, but try to incorporate it into your daily shop floor work. Being accepted on the shop floor is crucial for any successful change on the shop floor.