Lean is my life. Whenever I see someone working, I cannot help but to think about the work from a lean point of view. Every now and then I come across a little gem, where I am just thoroughly impressed with someone’s approach to manage and improve their work. During my winter vacation in Iceland, I came across just such a gem with an excellent corporate culture for continuous improvement. Let me introduce Te & Kaffi and its lean mindset.

Lean is my life. Whenever I see someone working, I cannot help but to think about the work from a lean point of view. Every now and then I come across a little gem, where I am just thoroughly impressed with someone’s approach to manage and improve their work. During my winter vacation in Iceland, I came across just such a gem with an excellent corporate culture for continuous improvement. Let me introduce Te & Kaffi and its lean mindset.

About Te & Kaffi

Te & Kaffi (which unsurprisingly means Tea and Coffee in Icelandic) is the largest coffeehouse chain in Iceland – which for a small nation of only 332,000 people means twelve coffee houses. And, in case you are wondering, even though Starbucks has 2000 times the number of shops worldwide, there are no Starbucks in Iceland.

Founded in 1984 by a coffee-loving couple, it now also roasts the coffee for many other coffee houses and stores, where it has 25% market share. They employ around 200 people, and plan to expand even more.

My Breakfast Observations

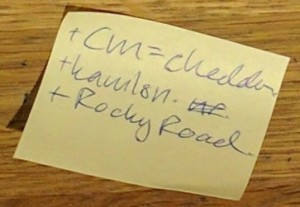

We had breakfast in the Te & Kaffi in the Kringlan Mall in Reykjavik. As usual, I observed the staff in their work to get inspirations for lean. First, everything went as expected. “What would you like … I can recommend … For here or to go ….” In other words, the usual coffee house interaction. However, after the saleswoman took our order and typed it into the cash register, she additionally wrote it down by hand on a small yellow Post-it note!

Alarm bells went off in my mind, screaming “Waste!” Why write it down by hand if you have it already in the computer? If it had to be done, couldn’t you use a pre-printed sheet of paper where you merely mark the details of the order? To me it just looked like a total waste of time to write it down by hand again.

Being always curious (with an additional tendency of being a smart-ass), I inquired why she wrote it down on paper. “It is the best way,” she said. I inquired why they don’t use a pre-printed sheet. They had tried that and it did not work. I inquired why they don’t use a printout from the cash register, and they have tried that too, and it also did not work.

While I had my (excellent) cinnamon roll, I pondered the responses. It totally went against my logic that writing by hand is better than the options I suggested. Not only does it take more time, there is also possibly a higher risk of mistakes, although her handwriting was much better than mine. I just did not get it!

While I had my (excellent) cinnamon roll, I pondered the responses. It totally went against my logic that writing by hand is better than the options I suggested. Not only does it take more time, there is also possibly a higher risk of mistakes, although her handwriting was much better than mine. I just did not get it!

I went back there the next morning for another breakfast, and – more importantly – for answers! Meeting the same woman again, I inquired why the alternative solutions did not work. The answer was quite unexpected. It had nothing to do with the time required for the paperwork, but with the space available.

During peak hours, they have a long line of customers, resulting in a long line of papers for these customers’ orders. They simply have not enough space to put all these papers. Only the yellow Post-its were small enough for the available space on the counter around the coffeemaker. They also have the additional benefit of being sticky, so they don’t move out of place if someone walks past. After all, they should keep a FIFO (First in – First out) sequence so the first customer is served first.

Again, my mind started working and I started suggesting ideas for improvement:

Again, my mind started working and I started suggesting ideas for improvement:

- Can you use a box like for index cards, and add the printouts at one side and remove them from the other side? Also already tried, did not work well.

- How about a sort-of clothesline with hangers for receipts? Another store already tried that, also without much success.

- Can you use a receipt spike, and just pull out the bottom one for the next order? Not sure if this works.

- What about magnets? Could you use them to hold papers at the metal counter? Also tried already, without much success.

While I still think that there must be a better solution for this problem, I noticed something else – the staff tried out many different things! And, in case you are wondering, the answers felt honest, and not the “Leave me alone, I have to work” type of conversation-enders. They truly spent lots of time and effort testing different solutions. I think I stumbled on a very nice example of a lean mindset for improvement.

The Lean Mindset for Improvement

It seems that Te & Kaffi managed to successfully involve their employees in their improvement efforts. The employees are actively working on Kaizen themselves. They also exchange improvement ideas with other shops. And, most importantly, it is not a central lean coach that does the improvement, but the workers themselves!

Continuing the conversation, I also found out that the owners not only permit this, but actively encourage the workers to change and adapt their workplace. Other changes initiated by the workers include, for example, a dedicated hot chocolate maker, which is much faster than making hot chocolate with the coffee maker.

This is employee empowerment! I usually try to avoid this word, since usually it is a buzzword in the corporate mission statement so managers feel good about themselves, but at Te & Kaffi the workers actually have the power to change their workplace. I also noticed lots of other little details that suggest creative solutions to little problems.

In my view, nobody knows the workplace as well as the people who work there. Properly managed, nobody will get as many good improvement ideas as the workers themselves. Let them experiment. Let them try to find a better way. Do not try to get the ideas from a Kaizen manager or Lean Change Agent, but have them empower the employees to create ideas and help them with implementing. From what I have seen, Te & Kaffi has managed this very well! Hats off to this Icelandic coffee chain!

Words from the CEO

The barista then recommended I get in contact with the CEO and the marketing manager, and gave me their emails (try that at Starbucks – hah!). Hence, I contacted them for a short interview. Here’s the overview:

They put in a lot of effort in providing the right environment to allow this kind of improvement mindset, including frequent exchanges between the shops. They also do not hire external managers, but pretty much all managers start out as normal workers/baristas who got promoted.

They put in a lot of effort in providing the right environment to allow this kind of improvement mindset, including frequent exchanges between the shops. They also do not hire external managers, but pretty much all managers start out as normal workers/baristas who got promoted.

This is very similar to the leadership at Toyota. Hence, they know the business from the bottom up and therefore most solutions to the different problems are homemade – and working!

Another improvement that the CEO was proud of was that their trays are “missing” a corner. While this makes the trays more expensive, it allows for easier cleaning and also easier drying while stacked. Overall, it improved the workflow. They also recently started to switch from the “call customer to pick up order” to “serve the customer at the table.” While it is a bit more work, it makes a much nicer atmosphere and customer experience.

Overall, a nice example of a good improvement mindset involving the frontline workers. I hope this was a good inspiration for you. Now, go out, start using not only the hands but also the brains of your people, and organize your industry!

PS: Shortly after this post, I visited Iceland again, presenting at the Lean Island Conference in Reykjavík!

Nice article Chris !

Viel Erfolg !

Interesting article. In fact I was writing the ’empowering people’ part in my thesis today. This example makes it more relevant. People are inherently good. No one wakes up in the morning with an intention to do ‘bad work’ for the day!

Also, sometimes we fail to appreciate the flexibility that simple tools like pen and paper provide!

Hi Shreyas, I would phrase your sentence different. Nobody starts their career with the goal to do bad work. But sometimes unfortunately events (like a bad manager) can “burn” people so that they hate their company and want to harm it, or at least don’t care if they do.

Nice article, Christoph. You have been such an inspiration to me, and I am 69 years old. Thanks!