This second post on continuously moving assembly lines will look at the math behind the correlation between the speed of the line (line takt or customer takt), the length of the line, and the amount of work that has to be done on the line. Luckily, the calculations are not very tricky. And, different from a pulsed assembly line, it is perfectly fine to have a continuously moving line that fits not a whole number but a fraction of parts to save space. The tricky part on how to assign the work to the workers will be discussed in the next post of this series.

This second post on continuously moving assembly lines will look at the math behind the correlation between the speed of the line (line takt or customer takt), the length of the line, and the amount of work that has to be done on the line. Luckily, the calculations are not very tricky. And, different from a pulsed assembly line, it is perfectly fine to have a continuously moving line that fits not a whole number but a fraction of parts to save space. The tricky part on how to assign the work to the workers will be discussed in the next post of this series.

Math

Posts including calculations and formulas.

Relation between Quantity and Cost in Manufacturing

As you surely know, it is more efficient to produce larger quantities. This is the economy of scale. In a recent post I talked about the Power of Six, a rule of thumb for the relation between lead time and cost. In this post I will show you a rule of thumb for the relation between quantity and cost. Credit for this rule goes to Juan Carlos Viela.

As you surely know, it is more efficient to produce larger quantities. This is the economy of scale. In a recent post I talked about the Power of Six, a rule of thumb for the relation between lead time and cost. In this post I will show you a rule of thumb for the relation between quantity and cost. Credit for this rule goes to Juan Carlos Viela.

The Power of Six: Time and Money for Parts of Your Value Stream

In my last post I presented you Rajan Suri’s Power of Six – the relation between turnaround time and product cost. In this post I extend his work to apply it to not the entire value stream but to segments of the value stream. Enjoy!

In my last post I presented you Rajan Suri’s Power of Six – the relation between turnaround time and product cost. In this post I extend his work to apply it to not the entire value stream but to segments of the value stream. Enjoy!

The Power of Six: Relation between Time and Money in Manufacturing

Time is money. You know that. But with respect to product cost and lead time, there is a rule of thumb that estimates this relation. Let me present to you the “Power of Six,” discovered by Rajan Suri. This gives you a rough estimate of how the lead time of your products influences the cost and vice versa. This first post looks at the original work, and my next post applies this rule also to segments of the value stream.

Time is money. You know that. But with respect to product cost and lead time, there is a rule of thumb that estimates this relation. Let me present to you the “Power of Six,” discovered by Rajan Suri. This gives you a rough estimate of how the lead time of your products influences the cost and vice versa. This first post looks at the original work, and my next post applies this rule also to segments of the value stream.

The Kingman Formula – Variation, Utilization, and Lead Time

The lead time of a system is heavily influenced by both the utilization and the variation. There are approximations available to estimate this relation, and one of them is the Kingman formula. In this post I would like to introduce you to this equation and describe the fundamental understanding of it. Luckily, you don’t really need the formula for your daily dose of lean. The equation itself has little practical use. However, this relationship is important for understanding the behavior of your production system. While you won’t use the Kingman formula to evaluate your production system, understanding the equation will help you in tweaking your system in the right direction.

The lead time of a system is heavily influenced by both the utilization and the variation. There are approximations available to estimate this relation, and one of them is the Kingman formula. In this post I would like to introduce you to this equation and describe the fundamental understanding of it. Luckily, you don’t really need the formula for your daily dose of lean. The equation itself has little practical use. However, this relationship is important for understanding the behavior of your production system. While you won’t use the Kingman formula to evaluate your production system, understanding the equation will help you in tweaking your system in the right direction.

On Running Changeovers

Changeover times and their reduction are popular topics in lean manufacturing. In this post I would like to introduce the idea of running changeovers for production lines. The idea behind it is simple, and probably many of you do it already. Nevertheless, I have found little info on it online. I also would like to go into more detail on the benefits of a running changeover in comparison to the alternatives.

Changeover times and their reduction are popular topics in lean manufacturing. In this post I would like to introduce the idea of running changeovers for production lines. The idea behind it is simple, and probably many of you do it already. Nevertheless, I have found little info on it online. I also would like to go into more detail on the benefits of a running changeover in comparison to the alternatives.

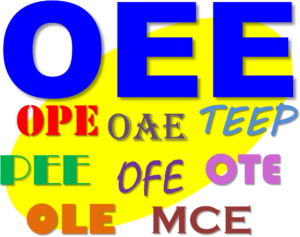

The Many Different Flavors of the OEE

If imitation is the sincerest form of flattery, the OEE (Overall Equipment Effectiveness or Efficiency) is indeed one of the most appreciated measures in lean. I counted at least eight different variants and adaptions of the basic OEE – although let me tell you that I am not impressed with all of them. Many of them seem to be theoretical academic constructs with little meaning for your shop floor. Also, identical acronyms and similar terms are often used in a completely different way, adding quite a bit to the confusion. On top of that, I think the OEE is used way too much in industry where it does not make sense, and many OEE numbers are heavily fudged. Anyway, let me show you the many different flavors of the OEE.

If imitation is the sincerest form of flattery, the OEE (Overall Equipment Effectiveness or Efficiency) is indeed one of the most appreciated measures in lean. I counted at least eight different variants and adaptions of the basic OEE – although let me tell you that I am not impressed with all of them. Many of them seem to be theoretical academic constructs with little meaning for your shop floor. Also, identical acronyms and similar terms are often used in a completely different way, adding quite a bit to the confusion. On top of that, I think the OEE is used way too much in industry where it does not make sense, and many OEE numbers are heavily fudged. Anyway, let me show you the many different flavors of the OEE.

Good and Bad Ways to Calculate the OEE

There are different ways to calculate an OEE. I know of at least three different ways. However, some of them are easier and more practical than others.

There are different ways to calculate an OEE. I know of at least three different ways. However, some of them are easier and more practical than others.

Maybe you have seen a formula similar to OEE = A x P x Q. I see this formula often, but for me it is a very impractical way to calculate the OEE. Let me show you why by comparing the three different ways to calculate an OEE.