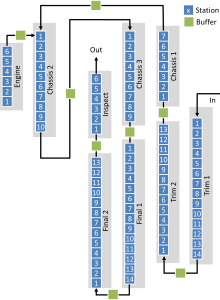

Toyota is a company that is constantly evolving, aiming to reduce waste. Over the last few years, I have heard about changes to the Toyota assembly lines to improve efficiency. During a recent trip to Japan, I was able to observe the assembly line at the Motomachi plant. In this post I will show the evolution of line layouts at Toyota.

Toyota is a company that is constantly evolving, aiming to reduce waste. Over the last few years, I have heard about changes to the Toyota assembly lines to improve efficiency. During a recent trip to Japan, I was able to observe the assembly line at the Motomachi plant. In this post I will show the evolution of line layouts at Toyota.

Toyota

Any posts related to companies from the Toyota Group, including Toyota Motor, Denso, etc., and its people.

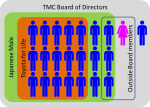

Consistency at Toyota – The Board of Directors of the Toyota Motor Company

The Toyota Motor Company (TMC) is one of the most well-managed firms in the world. Among multinational corporations, it is probably the most famous one. Since its founding in 1937, TMC has continuously improved. The question is, how did Toyota do that? What does Toyota do differently from other companies, who stumble from one problem into the next? I believe the corporate culture and style start with the behavior at the top. Hence, in this post I will look at the board of directors of TMC in more detail.

Japanese Standard Pointing and Calling (Video)

During my last trip to Japan, I finally took videos capturing the Japanese Pointing-and-Calling standard. Pointing and calling is a safety standard that started with Japanese train operators but now is widely used in industry. The idea is that whenever you confirm something, you not only look at it, but also point at it and call out your observation.

Internal Threat to the Toyota Production System Due to New Hiring Practices

Toyota with its Toyota Production System is the archetype of lean manufacturing, which also makes it to one of the most successful companies on earth. This success is due to outstanding cooperative management at Toyota; however, recent changes in hiring practices threaten the Toyota Production System.

Japanese Multidimensional Problem Solving

In the West, the standard approach for problem solving is to take a good look a the problem, after which a solution approach will pop into someone’s head. This approach is then optimized until the problem is solved. However, while this often ends up with one solution, it usually is far from the best solution possible. In Japan, a very different multidimensional problem-solving approach is common. Rather than just use any solution that solves the problem, they aim for the best solution they can find.