Leader standard work. Sometimes also called standard work for leaders. A term that floats around quite a bit in lean manufacturing, but I always find it hard to make it more specific. The idea follows the lean concept to standardize things, and tries to standardize the work of managers or leaders. The idea itself is not bad, but it always feels like nailing Jell-O to a wall. There are definitely some worthwhile elements, but sometimes it appears almost mystical. Let’s have a look:

Leader standard work. Sometimes also called standard work for leaders. A term that floats around quite a bit in lean manufacturing, but I always find it hard to make it more specific. The idea follows the lean concept to standardize things, and tries to standardize the work of managers or leaders. The idea itself is not bad, but it always feels like nailing Jell-O to a wall. There are definitely some worthwhile elements, but sometimes it appears almost mystical. Let’s have a look:

Introduction

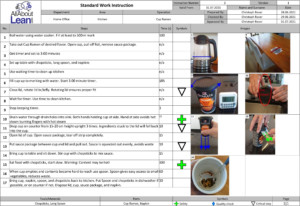

Work standards describe work in the necessary detail. Their purpose is for operators to do good work and to not miss a critical step, and for managers to be able to verify if the worker follows the standard. It is usually a list of steps. On a bigger scale, work standards help to reduce fluctuations (mura), and improve quality, cost, speed, or safety, i.e. reduce waste (muda).

Work standards describe work in the necessary detail. Their purpose is for operators to do good work and to not miss a critical step, and for managers to be able to verify if the worker follows the standard. It is usually a list of steps. On a bigger scale, work standards help to reduce fluctuations (mura), and improve quality, cost, speed, or safety, i.e. reduce waste (muda).

Most work standards are for frontline workers actually working on the products. The idea of leader standard work is to extend this standardization to supervisors and managers in order to also reduce fluctuations and waste. So far, so good.

What Works

Let’s start with the easy part: where standards actually work for managers. A work standard is useful only for repetitive work, or for the parts of the work that is repetitive. It is useless for work that is different every time. Managing others by its nature includes a lot of tasks that are not repetitive. More on that later.

But the repetitive tasks do benefit from standardization, also for managers. Hence, it is quite feasible to create standards or checklists for these repetitive elements. These could be work that is only for the managers, or it could be work that the manager has to do just like everybody else. A few examples:

- The plant manager has to attend a shop floor meeting every morning when he is in-house. The departments are Monday casting, Tuesday milling, Wednesday assembly, Thursday sheet metals, and Friday electronics.

- The shop floor manager needs to check and sign off the standardized production sheets for all departments daily.

- Business travel has to be requested using “Travel Request Form 2241.”

What Makes Standards for Leaders Difficult

Standards for leadership are more difficult than standards for operators. I already mentioned that the share of repetitive work goes down as you climb up in the hierarchy. This is often combined with the standards becoming fuzzier. If you assemble a product, there is one place where a component must go, and it is easy to verify if it is there or not. Hence, verifying the standard has a clear yes/no answer. If a standard requires managers to treat people with respect, how do you verify that? It is nearly impossible to give a clear yes/no answer, but you will end up with a wish-washy gray zone in between. Difficult! But there are even more problems.

For one, people usually do not like to be told how to do their work. This increases the more huff-puff-important a person is. Managers are more opposed to people telling them what to do than workers. This also depends on the culture in the company. In some companies, you need to always know everything (or at least pretend to do so) in order to make a career. Someone telling the manager how to do their work implies that the manager did not know how to do it before, which will hurt their career aspect.

For a historic example, Frederick Winslow Taylor (1856–1915) is well known for Taylorism, standardizing the work of operators. The American Society of Mechanical Engineers (ASME) took note and liked his idea. They elected him as their president in 1906 in order to reorganize themselves. Taylor got to work and started to tell all those important doctors, professors, and other huff-puffs how to do their work. This did not go down well. He got kicked out after less than one year. The ASME, which before his presidency regularly published papers about Taylorism, published almost nothing about him and his work afterwards. That’s what you get for telling important people how to do their work…

Finally, a standard needs to be verified by and occasionally observed by a manager. This, naturally, should be a manager from a higher hierarchy level. Yet, the higher up you go, the further away managers are from the real work, and the less time they have. Eventually at the top there will be nobody above the CEO. Overall, it is difficult to verify the correct use of a standard for managers by a higher-up manager.

What Does NOT Work

So far, the parts of leader standard work described above is pretty much a normal work standard, with the limitations that come with management tasks. But some sources for leader standard work go further, and that’s where it becomes more mythical than practical.

First, a work standard is a set of instructions on how to do a task. Standard work (or standardized work) is bigger, trying to fit the task in a takt time. It includes the customer takt, an analyses of the available capacity, line balancing, line layout, before eventually creating a work standard.

Please tell me, what is the takt time for managers? How many minutes per decision is their customer takt? Or what is their capacity in decisions per day? How does a management decision line layout look like? Overall, this does not work. While work standard and standard work are often confused, the additional parts of standard work does not fit well with management tasks. To me it feels like taking a (meaningful) buzzword (standard work), and applying it without understanding it.

But it gets worse. Some sources use “Leader Standard Work” to talk about leadership philosophy, general management behavior, going to gemba and using visual management, or, simply all of lean manufacturing. This is a meaningless mashing together of buzzwords. There is not even a good definition on what lean actually is. I believe lean is a culture, but I cannot even define it myself. What is the American/German/Indian/… culture? So, how on earth will you make a standard for a lean culture or philosophy??? Sorry, this is garbage.

Summary

In sum, management can benefit from using standards for repetitive tasks or the repetitive elements of tasks that can be described well. There are some difficulties, like managers always knowing better and having less supervision, but that works. Calling it “Leader Standard Work” for me is an unfortunate term since standard work includes, for example, a takt time, which does not work for managers. Including the whole lean philosophy and claiming it to be leader standard work is bad buzzword bullshitting. Hopefully this post helped you to pick the useful elements of standards for managers (please don’t call it leader standard work). No, go out, not only create standards for others but also use standards for yourself if applicable, and organize your industry!

P.S.: This post was initiated by a question from Tom. Thanks for asking!

Series Overview

- Standards Part 1: What Are Standards?

- Standards Part 2: Why and Where to Do Standards

- Standards Part 3: How to Write a Standard

- Standards Part 4: How to Write a Standard (Continued)

- Standards Part 5: How to Use and Improve a Standard

- Standards Part 6: Standardized Work

- Standards Part 7: How to Write a Work Standard

- Standards Part 8: Example for a Work Standard

- Standards Part 9: Leader Standard Work

Thanks for the review and deep dive into Leader Std Work. I thought I was missing something.

I emphasize and preach Leader Std Work as a way to provide a positive example to others and let them know that Lean isn’t just for the shop, rather it’s applicable in the office and boardroom too!

I would not be so quick to “throw Leader Standard Work” under the bus (sorry for the American metaphor). Leader Standard Work can easily cover employee development along with daily SQPD tasks. These development items could include coaching, although I support every moment as a coaching moment, and problem solving skill development a la an A3 process. The Takt time is calculated by using the leaders available time by the number of employees/associates/operators the leader is responsible for so, as an example, assuming that line leadership takes responsibility for the line team and area leaders take care of line leaders, and so on, the ‘span’ of control dictates the number of employees to be coached. Each leadership level will have a different balance in coaching/problem solving/ SQPD standard work elements. I have used Leader Standard Work from Line Leaders ‘down’ to the Plant Manager (using a Servant Leadership model).

Hello Scott, Leader Standard Work has some good and useful elements, but also some potential for bedazzlement. I try to keep these two separate. Use what works, ignore the fireworks.

Thanks Christoph for keeping things honest and direct! I’m in the middle of refreshing LSW in our plants, and its refreshing to come across your article amid all the hogwash out there on the subject.

Thank you Christoph for sharing your view on SWFL and you are right, if by SWFL we picture an SOP that the Leader should follow. My understanding of SWFL process is that it is not about specific guidelines on how a Leader should act, but more about clear ownership of his area of responsibility, which he tracks with specific metrics and he decides to book time through his week to manage them. In other words, my SW as a Leader would be more accurately described as Planned Work, which I believe I need, in order to achieve my targets. As the targets and responsibilities are moving, I may need to revise my SW for the future, adapting to the business needs. And of course a Leader cannot have SW for his entire day. The higher in the chain of command, the less booked time on routine activity he should need,

Hi Miltiadis, i was trying to figure out what you mean by SWFL. I am guessing it is not South-West Florida. The way you describe it it sounds very much like management by objectives.

It is interesting to see how standards change drastically as you navigate the hierarchy of a company. Rather than being a simple set of instructions standards at the leadership level become more abstract. The example you give about respect is a great one. Sure a standard can be for all managers to respect their employees, but how is that measured? At what point are you no longer meeting the standard. Overall I think it is critical for managers to receive regular feedback and from peers and employees in order to uphold these more ambiguous standards.

Christoph, I greatly appreciate the body of knowledge, hard work and dedication you are putting into delighting fans of lean with your insights. The first several articles in the standard work series are excellent. I want to share my perspective and a summary of my experience with the final topic, LSW

For me, leadership about getting results. Leader Standard Work can be a particularly useful tool, if well thought out, and applied with the right attitude, will become the best-known repetitive pattern of activities that represent the current most effective and least wasteful method of planning, organizing, controlling, and executing the owners work time to drive results. In simplest terms, LSW is a checklist of management and leadership activities that are performed on a daily, weekly, and monthly basis to do the right things with your time.

Leader standard work helps to focus its owner on the priority of the moment and can be an effective development tool in coaching for personal performance by utilizing catch-ball and 80/20 thinking. (Pareto Principle). A well-planned checklist of activities also effectively aligns the standard work between people who must collaborate within and between functional groups and management systems.

In coaching or mentoring one-on-one sessions the owner and his Sensei or coach should establish target conditions for how much of the work time should be standardized. This can range anywhere from 20% for executives to more than 95% for production operators with various leader roles having a greater or lesser degree of standardized work depending on a wide range of variables regarding their work content. The owner should review and track results daily and be honest enough to reflect and make note of variances and obstacles to achieving the SW plan.

The owner and coach should meet on a standard cadence (bi-weekly or monthly can be effective intervals) to review current state to analyze the actual results versus the plan. By working together with the intent of improving leader effectiveness, the coach can facilitate the owner in seeking to understand the obstacles and develop countermeasures to improve results. An immediate first step would be identifying conflicts and change the sequence or time spent on tasks, followed by PDCA to measure for improvement. Other things the owner may identify the need to change include personal work habits and behavior, develop better attitudes and mental models about what is important (Eisenhower Matrix), change the schedule plan to eliminate conflicts in collaborative work demands, to align with peers, increase or decrease the amount of time dedicated to certain tasks over time as capabilities improve, so that there is a better balance of work that drives results, and it is always important to consider adding or dropping activities from the checklist (Juggling KOAN) from time to time based on their relevance to the responsibilities and goals of the owner.

I have been extremely fortunate to have coaches who understood the purpose of the tool and always maintained a focus on respect and dignity for the challenges their team of leaders faced. The tool was never used to gain conformity or compliance. It was always used for personal growth and awareness of ways to self-develop and become a more effective manager and leader. If the tool is applied as a “gotcha” tool or to demean the owner for his or her shortcomings, as it often is in many western management cultures, then it’s effectiveness in continually developing people is rendered useless for obvious reasons.

hello Jeff, thanks for the good (and long) comment. What you describe feels more like target setting and general coaching. This could be seen as part of leader standard work, to have a regular review of the current state vs. the targets. Good comment!

Professor,

Thanks or your insights in this post and series, I have enjoyed reading and learning from them. It’s interesting how you said that lean is a culture and philosophy. I think that that is a very appropriate way to describe it as otherwise is is difficult to describe in its entirety. This is especially true for the uninitiated. I also found it so important that you mention that you must adapt that you are using depending on who it is for. Your example was managers using tact time, that is a great example because it would never be worth the time solving for that as it is far to variable.

Thanks.

Many thanks 🙂