Honda is the largest motorcycle manufacturer in the world with around 17 million motorcycles sold in 2017 (compared to number 2 Yamaha with around 5.2 million, 2015 figures). In January 2018 I had a chance to visit their Honda Kumamoto plant. This plant gave me a much better and very different impression than the Honda Sayama automotive plant.

Honda is the largest motorcycle manufacturer in the world with around 17 million motorcycles sold in 2017 (compared to number 2 Yamaha with around 5.2 million, 2015 figures). In January 2018 I had a chance to visit their Honda Kumamoto plant. This plant gave me a much better and very different impression than the Honda Sayama automotive plant.

Plant Tour

The Grand Tour of Japanese Automotive – Honda Sayama

Honda is the seventh-largest car maker in the world (in 2016). It is the largest maker of motor bikes and internal combustion engines overall. During my Grand Tour of Japanese Automotive, I was able to visit two of their plants: Sayama, where they produce cars, and Kumamoto, where they produce motor bikes and generators. These two plants are very different from each other. Let me give you what I found.

Honda is the seventh-largest car maker in the world (in 2016). It is the largest maker of motor bikes and internal combustion engines overall. During my Grand Tour of Japanese Automotive, I was able to visit two of their plants: Sayama, where they produce cars, and Kumamoto, where they produce motor bikes and generators. These two plants are very different from each other. Let me give you what I found.

The Grand Tour of Japanese Automotive – Nissan

Nissan by itself would be the sixth-largest car maker (5.5 million vehicles in 2016), although it is now a part of the Renault-Nissan-Mitsubishi alliance, which was the largest car maker in 2017. It is also the world’s largest producer of electric vehicles.

Nissan by itself would be the sixth-largest car maker (5.5 million vehicles in 2016), although it is now a part of the Renault-Nissan-Mitsubishi alliance, which was the largest car maker in 2017. It is also the world’s largest producer of electric vehicles.

As part of my grand tour of Japanese automotive plants, I visited their Yokohama and Iwaki plants, which both make engines. In my view, the manufacturing performance of Nissan is comparable to that of Toyota, making it also one of the most efficient car makers worldwide. Let me show you what I found.

The Grand Tour of Japanese Automotive – Overview and Toyota

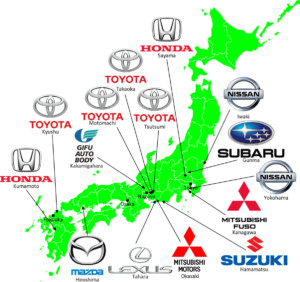

During Winter 2017–2018, I spent five months in Japan. As part of this visit, I was able to visit factories of all seven Japanese car makers as part of my Grand Tour of Japanese Automotive Plants.

During Winter 2017–2018, I spent five months in Japan. As part of this visit, I was able to visit factories of all seven Japanese car makers as part of my Grand Tour of Japanese Automotive Plants.

This was extremely insightful, and I learned a lot about the differences between the Japanese car makers. Let me give you an overview and some details on Toyota plants before firing off a series of blog posts on the different Japanese automotive companies.

Continued Evolution of the Toyota Assembly Line

Toyota is one of the the most visionary car makers with respect to its manufacturing. They continuously and radically evolve and update their production system. Recently I learned about their new “flexible assembly line.” Now, you’ve probably heard about Toyota’s flexible assembly lines producing multiple products on the same line. That is old hat; they’ve done that for thirty years. Their new flexible assembly line involves a completely different aspect of flexibility, with which Toyota surprised me (again). Let me show you …

Toyota is one of the the most visionary car makers with respect to its manufacturing. They continuously and radically evolve and update their production system. Recently I learned about their new “flexible assembly line.” Now, you’ve probably heard about Toyota’s flexible assembly lines producing multiple products on the same line. That is old hat; they’ve done that for thirty years. Their new flexible assembly line involves a completely different aspect of flexibility, with which Toyota surprised me (again). Let me show you …

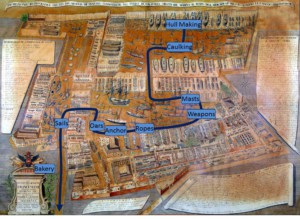

Material Flow in the Arsenal of Venice 1797

Whenever I am in Venice, I try to visit the Museo Storico Navale, near the entrance to the Arsenal of Venice. This museum has a set of beautiful detailed maps by Abbot Maffioletti showing the Arsenal of Venice in 1797, 1798, and “After Napoleon.” You can see in great detail the different steps needed to build and equip a sailing vessel. In this post, I will explain the material flow of the Arsenal of Venice, which was the largest industrial site in Europe and possibly in the world during its time. Be warned, this post is rich in images. The material flow is partially based on the master thesis of my student Maren-Linn Janka.

Whenever I am in Venice, I try to visit the Museo Storico Navale, near the entrance to the Arsenal of Venice. This museum has a set of beautiful detailed maps by Abbot Maffioletti showing the Arsenal of Venice in 1797, 1798, and “After Napoleon.” You can see in great detail the different steps needed to build and equip a sailing vessel. In this post, I will explain the material flow of the Arsenal of Venice, which was the largest industrial site in Europe and possibly in the world during its time. Be warned, this post is rich in images. The material flow is partially based on the master thesis of my student Maren-Linn Janka.

The Arsenal of Venice

The Arsenal of Venice was one of the the largest industrial sites in Europe in the 16th century. This was the hub of Venetian ship building, supporting the power of the Venetian republic. Both warships and merchant vessels were built there.

It is also known for the organization of its work. Sometimes it is listed as the world’s first assembly line, although in my view this may be a bit of a stretch. While they achieved a lot, there was also a lot of chaos. In this post I present you with a bit about the Arsenal in general, as well as some detailed maps by Abbot Maffioletti from 1797 and 1798. In my next post I will go into much more detail on the material flow based on these maps.

Toyota’s and Denso’s Relentless Quest for Lot Size One

A famous step toward perfection in a lean production system is a lot size of one. However, few people realize what enormous effort and rigor Toyota applies to achieve this goal. During my visit to a Toyota plant and the APMS conference in Tokyo in 2015, I saw quite a few stunning examples of this quest. Let me show you …