In my last post I talked about what you need for Cardboard Engineering. In this post I will show you how to do a Cardboard Engineering workshop. Spoiler: Keep in mind that the goal is not to just put something together but to try out different options (and I will repeat this a few times in this post). It is very easy to have fun with cardboard while learning very little about the problem you want to investigate!

In my last post I talked about what you need for Cardboard Engineering. In this post I will show you how to do a Cardboard Engineering workshop. Spoiler: Keep in mind that the goal is not to just put something together but to try out different options (and I will repeat this a few times in this post). It is very easy to have fun with cardboard while learning very little about the problem you want to investigate!

Problem Solving

Cardboard Engineering – Preparation

Cardboard Engineering (CBE, sometimes also Cardboard Modeling) is in general the building of models from cardboard. These models are usually quick and inexpensive to build, but often not very durable. In lean manufacturing, these cardboard models are often workstations or entire assembly lines to test different concepts before building the whole thing in more expensive and time-consuming aluminum and steel. This allows faster and easier experimentation with different concepts to improve your production system.

Cardboard Engineering (CBE, sometimes also Cardboard Modeling) is in general the building of models from cardboard. These models are usually quick and inexpensive to build, but often not very durable. In lean manufacturing, these cardboard models are often workstations or entire assembly lines to test different concepts before building the whole thing in more expensive and time-consuming aluminum and steel. This allows faster and easier experimentation with different concepts to improve your production system.

Example of Problem Solving – Japanese Men’s Relay Team Rio 2016

Good problem solving can seriously help you with the performance in your plant. John Shook recently pointed out another nice example to me: the Japanese Men’s 4x100m relay team during the 2016 Olympics in Rio. They were the underdogs, with none of their team having ever run 100m in under 10 seconds. Yet they stunningly won the silver medal! They achieved this through good problem solving. Let me show you the details:

Good problem solving can seriously help you with the performance in your plant. John Shook recently pointed out another nice example to me: the Japanese Men’s 4x100m relay team during the 2016 Olympics in Rio. They were the underdogs, with none of their team having ever run 100m in under 10 seconds. Yet they stunningly won the silver medal! They achieved this through good problem solving. Let me show you the details:

All About 5 Why

My Workshop Structure for Creative Problem Solving

In lean manufacturing – or in fact, in any kind of production system – you have to solve problems. Depending on the problem, you may need a creative solution and have to access the wisdom of the crowd. For this I have a workshop structure that I frequently use for problems that have lots of different options. Let me show you my workshop structure with which I’ve had quite good results.

In lean manufacturing – or in fact, in any kind of production system – you have to solve problems. Depending on the problem, you may need a creative solution and have to access the wisdom of the crowd. For this I have a workshop structure that I frequently use for problems that have lots of different options. Let me show you my workshop structure with which I’ve had quite good results.

How to Do Brainstorming

A lot of lean is about problem solving, and most of these problems are complex and difficult. Otherwise, someone would have solved them already. Hence, I would like to introduce you to different creativity techniques for problem solving. Most of them can be used in groups to access the collective wisdom and creativity. Most of them are also suitable to develop a number of alternative solutions, of which you can pick the best ones (see my previous post on Japanese Multidimensional Problem Solving). Many of them can be combined in sequence. Let me start with the most common one, brainstorming:

A lot of lean is about problem solving, and most of these problems are complex and difficult. Otherwise, someone would have solved them already. Hence, I would like to introduce you to different creativity techniques for problem solving. Most of them can be used in groups to access the collective wisdom and creativity. Most of them are also suitable to develop a number of alternative solutions, of which you can pick the best ones (see my previous post on Japanese Multidimensional Problem Solving). Many of them can be combined in sequence. Let me start with the most common one, brainstorming:

More on TWI Programs

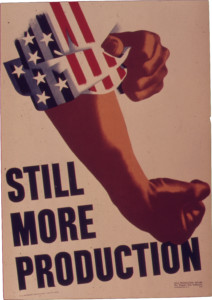

The TWI Program during World War II was very successful. Besides the Job Instructions, Job Methods, and Job Relations, a few other modules were developed, some of them internally. After the war, different institutions took over what the US government abandoned in December 1945. These follow-up institutions were the TWI Foundation and the TWI Inc. in the US; but it was also continued by the British TWI Service and the New Zealand TWI Service, and it was especially successful in Japan. Altogether, TWI was used in around seventy countries in 1960, although with quite different intensity and much less than when the US government used it through the war. This is the last in a series of five posts on TWI.

The TWI Program during World War II was very successful. Besides the Job Instructions, Job Methods, and Job Relations, a few other modules were developed, some of them internally. After the war, different institutions took over what the US government abandoned in December 1945. These follow-up institutions were the TWI Foundation and the TWI Inc. in the US; but it was also continued by the British TWI Service and the New Zealand TWI Service, and it was especially successful in Japan. Altogether, TWI was used in around seventy countries in 1960, although with quite different intensity and much less than when the US government used it through the war. This is the last in a series of five posts on TWI.

JM: Training within Industry – Job Methods

Job Methods is the TWI module focusing on improving the workplace. The method is a basic four-step process focused on optimizing mechanical work. The underlying approach is good. The documents from 1945, however, put the improvement squarely on the shoulders of the supervisor.

Job Methods is the TWI module focusing on improving the workplace. The method is a basic four-step process focused on optimizing mechanical work. The underlying approach is good. The documents from 1945, however, put the improvement squarely on the shoulders of the supervisor.

My belief is that the workers should be involved much earlier and that the decision of what to improve would also benefit from more attention. But the basic method is still sound. The TWI people also saw this problem, but their management told them that it is “good enough.” Hence this module saw a lot of improvements after 1945. Yet, it was the smallest of the three main programs. Let me show you the TWI Job Methods in more details. This is the fourth in a series of five posts on TWI.